Another 4.6 stroker, but with aluminum head and supercharger

Posted: February 11th, 2009, 9:51 am

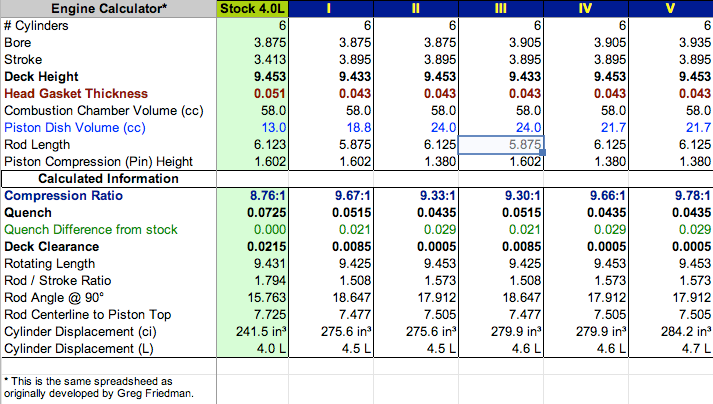

For my High Performance Engines I class, I'm going to work on a 4.6 stroker for my bench racing build (actually building it would be in the HPE II class), and using this as a guide:

Then add what I learn in class to that to make something a little different. I'm playing around with the idea of using the Hesco aluminum head for 2 reasons:

1) I have to go with a 00+ 4.0, and the easiest one to find is in a JY XJ, which of course has the 0331 head, not something I want to take the risk of running in a stroker motor that I'm going though with a fine tooth comb. And trying to find a TJ in a JY is near impossible around hear, let alone a 02+(well I could always try to find a 4.0 WJ I guess).

2) I found out from class the rule of thumb on iron vs. aluminum head is, aluminum head can allow you to run an extra point of compression on the same grade gas, I.E. a engine with an iron head would have to run premium gas with a 9.X:1 compression ratio, where as the same engine with an aluminum head could run 10.X:1 ratio on the same premium gas. And the rule of thumb on compression is 1:1 = 60 hp. So aluminum head = 60hp. This is due to the aluminum being able to "flex" more than an iron head, absorbing the force of combustion better. Not to mention the 30hp gain the head gives on a stock engine, in addition to it being lighter, lowering coolant, and combustion chamber temps, and so on.

Then on top of all this, I'll throw this on top:

http://www.kennebell.net/supercharge...wrangler40.htm

I'm guessing somewhere in the ballpark of 450hp and 500ft/lbs, and I think that's thinking pretty conservative.

4.2L 3.895" stroke crank

4.0L 6.125" Eagle rods

+0.030" bore pistons

9.5:1 CR aprox

Hesco aluminum cylinder head

Ford 24lb/hr injectors with stock 49psi FPR

Not sure on piston dish, or the cam yet,

The goal here is tow-end torque, and lots of it. Stroked for better low-end torque; Bored only to refresh the cylenders; Aluminum head for the compression bonus, the cooling and weight are just added bonuses; Twin-screw supercharger for the better low end power delivery over centrifical superchargers(Vortech), or turbos, and cooler intake charge than a Roots type (I don't know of any Roots type blowers for the I6).

Now for my actual build, I'll forgo the supercharger, and posisibly the aluminum head for cost reasons, but probably keep most of the internal specs(bore, stroke, rod length)

Then add what I learn in class to that to make something a little different. I'm playing around with the idea of using the Hesco aluminum head for 2 reasons:

1) I have to go with a 00+ 4.0, and the easiest one to find is in a JY XJ, which of course has the 0331 head, not something I want to take the risk of running in a stroker motor that I'm going though with a fine tooth comb. And trying to find a TJ in a JY is near impossible around hear, let alone a 02+(well I could always try to find a 4.0 WJ I guess).

2) I found out from class the rule of thumb on iron vs. aluminum head is, aluminum head can allow you to run an extra point of compression on the same grade gas, I.E. a engine with an iron head would have to run premium gas with a 9.X:1 compression ratio, where as the same engine with an aluminum head could run 10.X:1 ratio on the same premium gas. And the rule of thumb on compression is 1:1 = 60 hp. So aluminum head = 60hp. This is due to the aluminum being able to "flex" more than an iron head, absorbing the force of combustion better. Not to mention the 30hp gain the head gives on a stock engine, in addition to it being lighter, lowering coolant, and combustion chamber temps, and so on.

Then on top of all this, I'll throw this on top:

http://www.kennebell.net/supercharge...wrangler40.htm

I'm guessing somewhere in the ballpark of 450hp and 500ft/lbs, and I think that's thinking pretty conservative.

4.2L 3.895" stroke crank

4.0L 6.125" Eagle rods

+0.030" bore pistons

9.5:1 CR aprox

Hesco aluminum cylinder head

Ford 24lb/hr injectors with stock 49psi FPR

Not sure on piston dish, or the cam yet,

The goal here is tow-end torque, and lots of it. Stroked for better low-end torque; Bored only to refresh the cylenders; Aluminum head for the compression bonus, the cooling and weight are just added bonuses; Twin-screw supercharger for the better low end power delivery over centrifical superchargers(Vortech), or turbos, and cooler intake charge than a Roots type (I don't know of any Roots type blowers for the I6).

Now for my actual build, I'll forgo the supercharger, and posisibly the aluminum head for cost reasons, but probably keep most of the internal specs(bore, stroke, rod length)