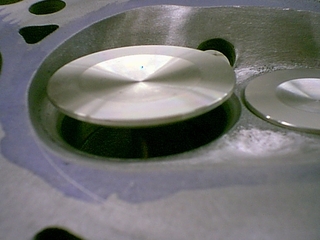

SilverXJ wrote:They are for the core alignment at the factory for machining processes.

I here you, and I'm inclined to believe that's the purpose also, but playing devil's advocate here, these things do resemble a large golf ball dimple, and we know that would create a turbulence. In a reverse flow cylinder head [non-cross flow head], would you get a "preference" to "hug" the region of the chamber closest to the in-and-out ports leaving the region further away vulnerable to lower flow and poorer "clean-out" like in chamber 1? But, if you added some sort of surface resistance, as in chamber 2, it

could help to "push" the flow back to the far side of the reverse flow chamber preventing the dead zones that surly would be there. Just saying...something to ponder there are not many modern reverse flow heads anymore, and if there were, what engineering tricks would be employed?

You do not have the required permissions to view the files attached to this post.