The Vehicle; 2000 TJ that my S.O. named Keekee. The best photo I have of it at the moment...

I purchased this a few years ago with about 80k miles. I've been using it as a DD until about a year ago when it started knocking pretty bad. After picking up a cheap DD I tore into it. Turns out it was a broken piston skirt. After debating different options I decided to go the stroker route.

I started off doing a bunch of reading and making a spreadsheet to calculate static/dynamic comp. ratios among other things. Then I got ahold of Russ and started asking questions about what he offers. I ended up getting most of the parts from him. Here's the basics of the build;

12wt. crank (craigslist find)

Bushed Scat rods

Russ' 0.060 over Race Tec pistons, 22cc chambers

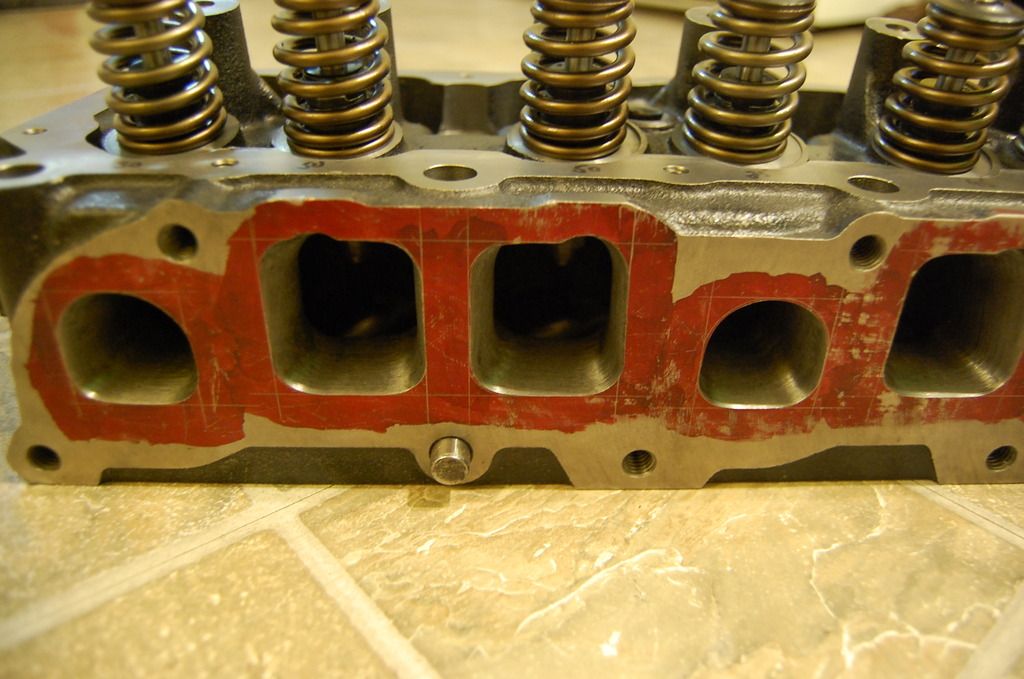

New Clearwater head w/LS valves/springs & port work

Comp 68-232-4 Cam

On to some photos...

Pistons right before dropping of at the machine shop.

Big box of miscellaneous parts.

Camshaft... 68-232-4.

Bushed Scat rods.

Rollmaster timing set.

A few shots of the new head and Russ' work.

I went cheap on an ebay header. It seemed to match up to the block fine so I decked the mating surface, bead blasted it, and did a couple coats oven baked ceramic paint. I don't have a good shot of the intake manifold, but I coated/baked it with the same ceramic paint.

I bored out the throttle body and CNC'd a new butterfly valve. I ended up getting it pretty close right out of the CNC but it still needed a little tweaking by hand.

In the interest of free time I ended up having the shop assemble it for me. I've never done a complete rebuild and was planning on doing this one myself, but after a few delays I wanted to get it on the road ASAP.

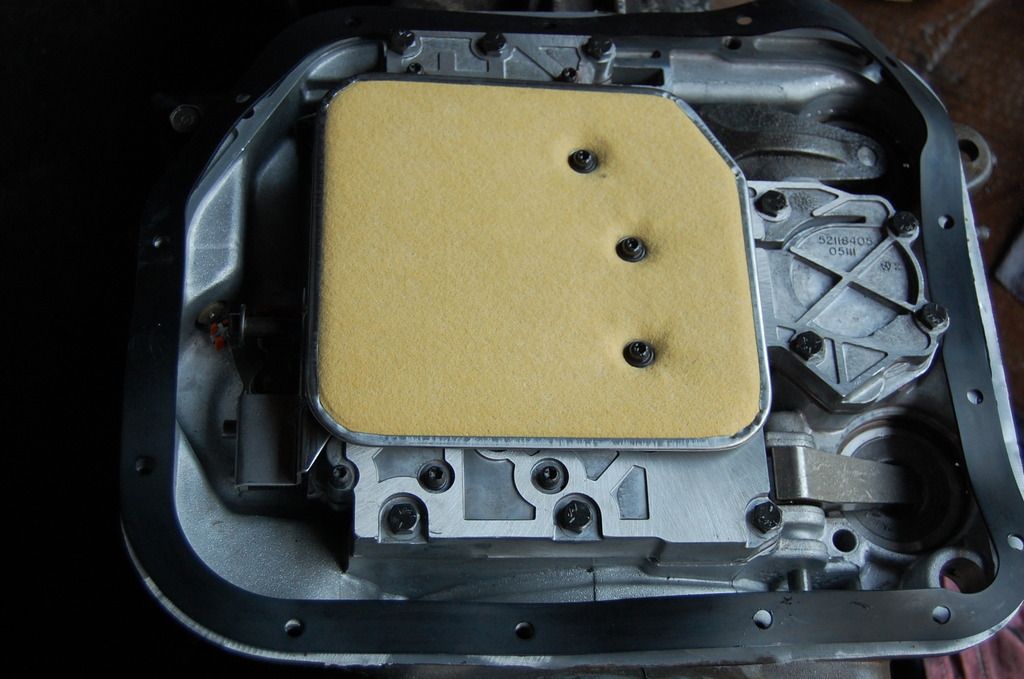

While it was out I cleaned out the valve body and replaced the filter.

Last year I was worried about the transmission overheating while in the dunes. I threw in a secondary transmission cooler in front of the radiator. I also added an external filter & temperature gauge (still need to grab some photos).

I noticed what looked like significant wear on the pump shaft... Has anyone ever seen this before?

Engine bay before install. It was in really good shape rust wise (as far as Michigan Jeeps go) having only seen one winter, but I went ahead and threw a couple of coats of Por15 over the front half or so of the frame.

Just after getting it dropped in.

The first real issues in the build came when trying to install the intake manifold. You can't tell, but the cheapo exhaust header was holding the intake manifold up & keeping it from seating fully. At the time it looked like more than I wanted to grind/bend away, so I ordered an aFe header.

Here's a quick comparison of the two. The aFe is a lot better quality.

I need to get some updated photos, but it's back in one piece and running well. Wideband/temps/oil pressure all look good. I still have a few issues and items to wrap up, but I'm pretty happy with it thus far.

Issues

- I have a ticking that I'm 99% convinced is coming from the bellhousing area. It was more noticeable right at startup when in drive/reverse, but has since faded in intensity. I checked the flex plate when it was off. It looked ok but I may have missed something. Double checked the torque converter bolts; All tight. Maybe something to do with that shaft wear? I don't really want to drop the tranny but it might be the only option.

- Cruise control was working after the rebuild but stopped.

- Air bag light recently came on.

Still To Do

- Fix above issues... primarily the ticking

- Possibly send oil out for analysis... Should I wait to get some standard (not break-in oil) oil in it and put some miles on it first?

- Get a cat/muffler ordered and ditch the stock exhaust. Any suggestions on a muffler? I don't want anything super loud.

- Install zeitronix ZT-2 & log some data/send out for a tune

- Possibly get it on a dyno