One other issue in my own personal build which was with a Mopar 229, is that my cam would not fully install, it would get stuck when reaching the last set of bearings. I WAS able by way of turning the cam around to get the front of the cam in the front cam bearing, and with the rear cam plug removed, the rear of the cam in the rear cam bearing meaning the issue was with #2 or #3 cam bearing/cam journal. It also did this with the stock cam. I took it back to the machinist with BOTH cams, he called back and said after installing a new set of bearings it did the same thing and he ending up have to hone the #3 block journal, and install a 3 set of cam bearings. Then it hit me that #3 is almost always the cam bearing that fails. Coincidence?

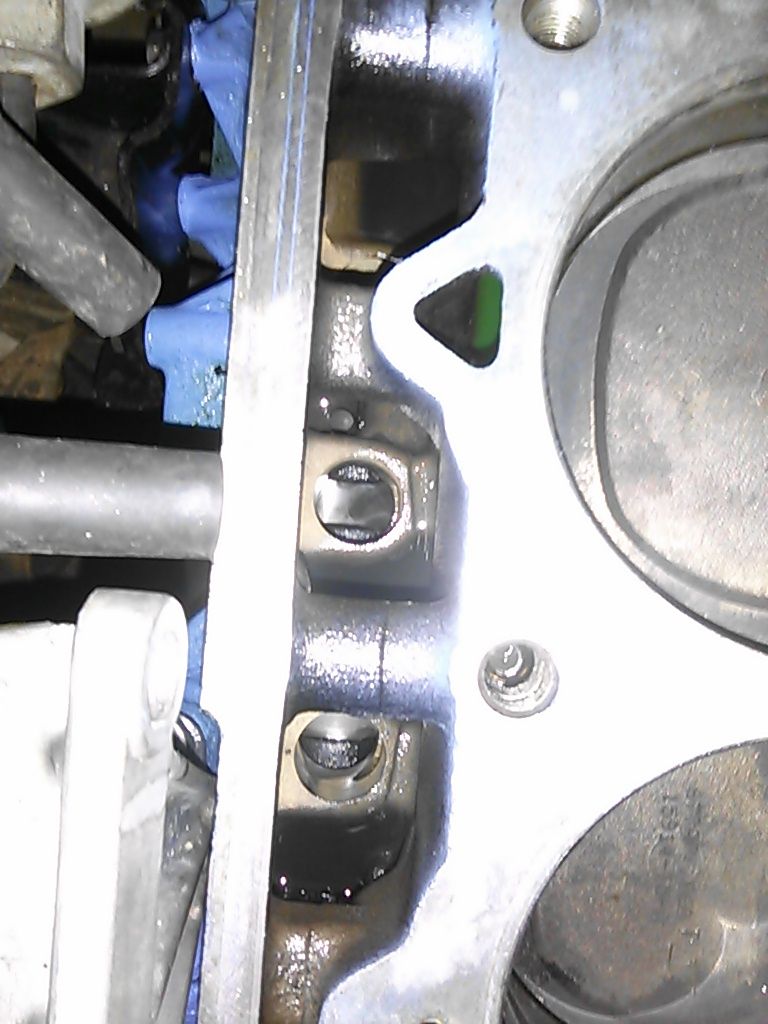

Here are some pics of AMCEagles narrow cam in his block, it would seem to me that in that particular lobe and lifter bore there would be very little if any lifter spin, the edge of the lifter is NOWHERE near the edge of the lifter bore. Now what causes THAT? If we can answer that I think we can come up with a fix for all cam longevity issues. Are the narrow cam cores meant to line up with 4.2 lifter bores vs 4.0 lifter bores, is there a difference? Should narrow cam cores be used with 4.2 cam gears, which may allow the cam a more rearward position, is there a difference? And I don't mean a part # difference but a measurement of an actual 4.2 cam gear an current 4.0 cam gears, with regards to how far they push the cam in. AND could all of this explain cam/distributor gear failures, as it relates to cam installation depth.

I have included an OPTIMAL cam lifter diagram and AMCEagle's installed narrow cam lobe/lifter relationship pics.