Got my block back up on the engine stand the other night and was just reviewing information in my head thinking about it. After reading up more on other sites and skimming the net reading books…(research doesn't ever stop)

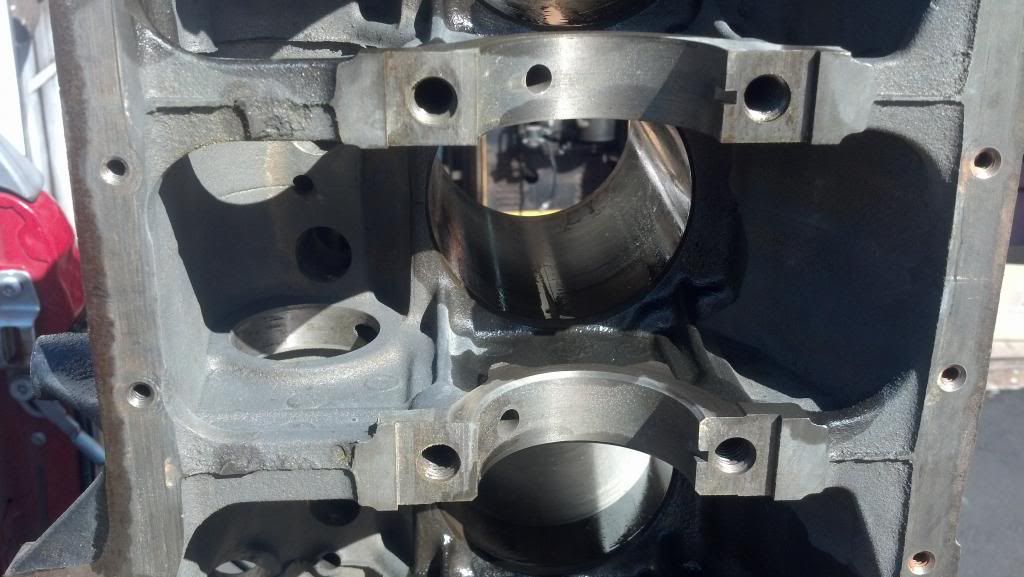

I have decided the taking the block to get it cryo'd would be the next best step (me thinks). After that I will do the block fill. Only planning on going up to right under the freeze plugs. From what I have read up on for doing the block fill. Rinse thoroughly to insure all acid/caustic agents are removed. Blow out with compressed air and dry. Hard Blok has some instructions on container I will review. As for set time to work with material takes about 30-40min. Before pouring: Install and tightening my main caps and head with gasket. This helps to insure any torque/distortion on the block that might change dimensions to be consistent from my understanding. Tapping on the block to work any air bubbles out and should setup firm within 24 hours (rubber mallet should work fine - I think i'll put my daughter to work). I'll probably let setup for a few weeks though considering the time of year. Should get over 65 degrees a few times here in Southern California in that time. Then I will take it to the machine shop for bore, deck height verification, decking according to internals (I have yet to order).

Am I missing anything…

Found another good reference build on another site. It's not a stroker but a good build thread non-the less.

http://www.forabodiesonly.com/mopar/sho ... hp?t=89636

And a GREAT

reference to understanding the importances of decking, piston to deck clearance and quench quote from the above link.

In regards to quench, you want it and I'll tell you why. When you have quench, whn the piston comes up it will squeeze the mixture out from between the quench areas on the piston and head at a very, very high rate of speed. This not only helps quell detonation but adds torque as well as it homoginizes the air/fuel mixture within the cylinder and there are no dead spots that will tend to detonate under compression as the AF is kept moving at a high rate of speed. In general, much higher compression ratios can be run with lower octane fuel and more power produced in similiar engines.

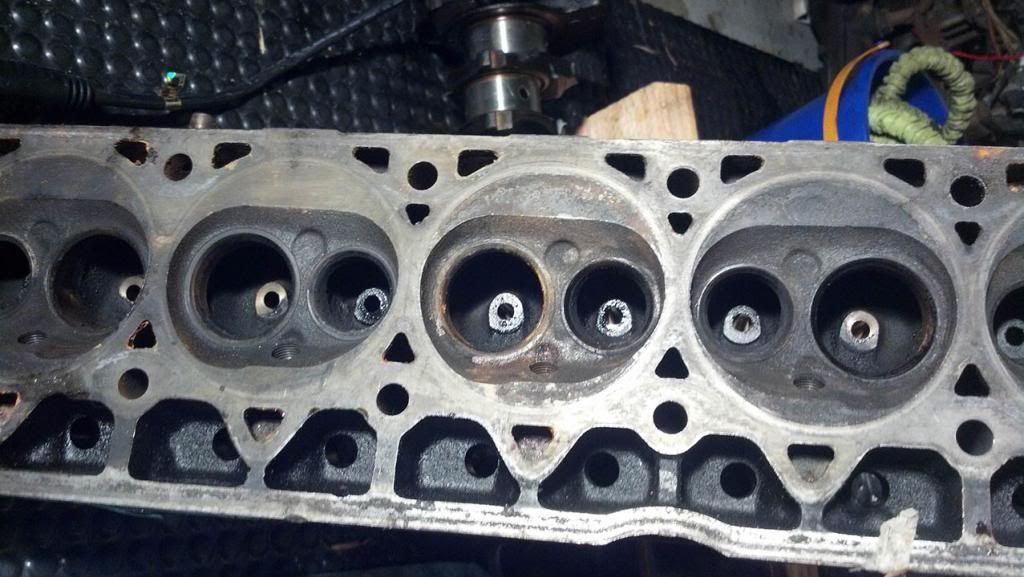

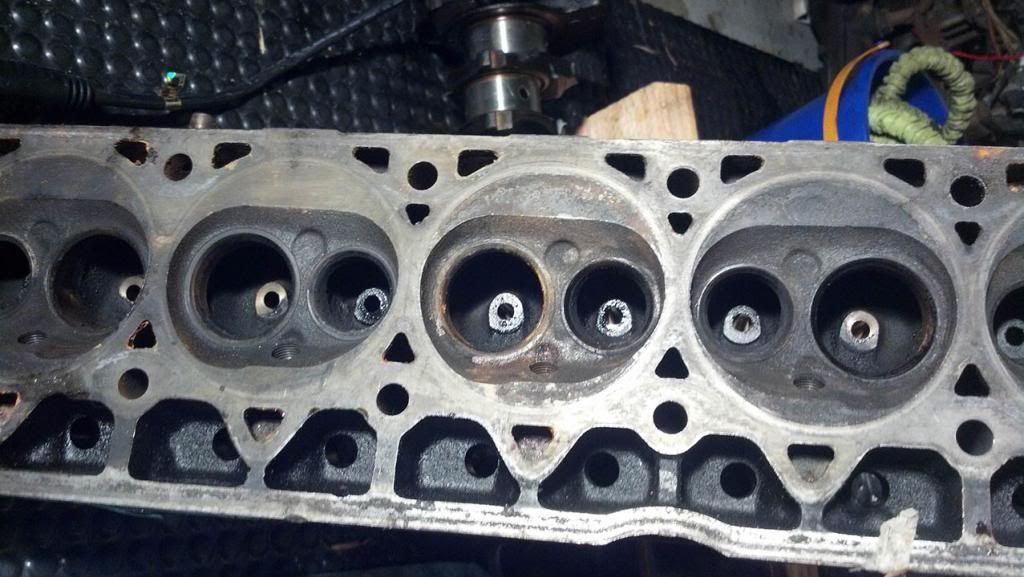

For quench to have any effect, there must be quench pads on both the piston and head. If you take a look at my previous pictures of my pistons and head, you'll see the pads on both. The piston to head clearance should also be less than .060" and smaller is better although a builder has to allow for piston expansion and rod stretch on any given build. I like to shoot for .040" but I know many people who get away with .025" but that is way pushing it.

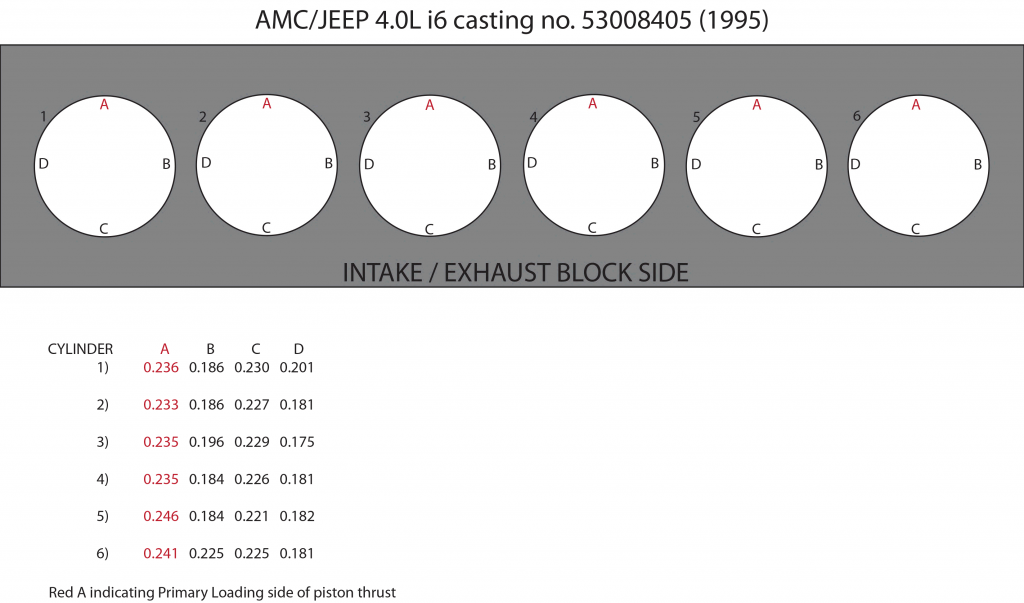

After first having my head and block decked for straightness, I mocked everything up and found that the piston was still .033" in the bore. So here we have this lovely compact head chamber with a generous quench area and pistons with quench pads but it's not being utilized by the factory. This is mostly due to manufacturing time limitations and generous casting tolerances.

For me to achieve quench on this build with a .040" gasket I had to have the block milled an additional .030". Why not .033"? Because the rod length tolerance is .002" and that must be brought into the equation.

I hope this answered your questions.

original post by RAMCHARGER on the above mentioned site.

I'm still in search of an aftermarket girdle. One of the other guys on here used to make them but couldn't get in contact with him via this site 8(

I liked the screen and girdle setup SilverXJ has on his build. I was looking at a girdle setup that would be more on the outside instead of on the spine of the crank. Having is setup as helping rigidity as well as a scrapper and screen 3-1 deal. Anyone have any ideas on any existing something like that?

recap:

1) hot tanked

2) magna fluxed

3) sonic'd

4) acid dipped

going to now:

5) cryo

6) fill block

7) bore, hone, and trim deck as needed for square/flatness

(might come back after rods/pistons/crank go in for mockup and decking is checked for piston to deck clearance)

8) order pistons