Cam bearings failed yet again... please help

- SilverXJ

- Global Moderator

- Posts: 5790

- Joined: February 14th, 2008, 7:14 am

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

- Location: Radford, Va

Re: Cam bearings failed yet again... please help

That is a 100% indication of cam walk. Interestingly in my cam bearing issues the bolt never made contact with the cover.

I would really like to know exactly what aspect causes the cam to walk and why it only happens in some builds.

I would really like to know exactly what aspect causes the cam to walk and why it only happens in some builds.

2000 XJ. 4.6L stroker

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

-

shawnxj

- I love this board

- Posts: 413

- Joined: March 30th, 2009, 7:30 pm

- Vehicle Year: 1988

- Vehicle Make: jeep

- Vehicle Model: cherokee

- Location: portland, tx

Re: Cam bearings failed yet again... please help

i've asked 4 lunati techs the same question and they all swear that a lunati came will not walk and that the stock pin and spring are all that's necessary. it's 1 of the reason i'm kinda dragging my feet on starting this thing because i can't afford to have to replace the cam and bearings in a month. only reason i haven't done the solid pin like you did is because i don't want to wear a hole through the timing cover like yours was starting to. i guess 1 way or the other this thing is getting fired off this weekend. can't really drag my feet anymore

- SilverXJ

- Global Moderator

- Posts: 5790

- Joined: February 14th, 2008, 7:14 am

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

- Location: Radford, Va

Re: Cam bearings failed yet again... please help

I don't think his was starting to wear a hole through the cover, but the bolt touched it enough to leave an impression and the hold head is a rather nasty looking thing. And its only a select few that have cam walk, but it looks like the list is growing for some reason. Prior to mine I only found two other people with fried cam bearings. One has due to a clogged oil pump and the other was from another problem with the cam gear. After that maybe 5 or so people on here have run into failed bearings.

2000 XJ. 4.6L stroker

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

-

dwg86

- Donator

- Posts: 1251

- Joined: February 13th, 2008, 6:20 pm

- Stroker Displacement: 4.6

- Vehicle Year: 2003

- Vehicle Make: Jeep

- Vehicle Model: Wrangler

Re: Cam bearings failed yet again... please help

A solid pin will not exert any more force than a spring and pin. A solid pin should have less force on the timing cover than a spring keeping constant pressure on the pin plus the action of the cam walking and pushing on the pin.shawnxj wrote:i've asked 4 lunati techs the same question and they all swear that a lunati came will not walk and that the stock pin and spring are all that's necessary. it's 1 of the reason i'm kinda dragging my feet on starting this thing because i can't afford to have to replace the cam and bearings in a month. only reason i haven't done the solid pin like you did is because i don't want to wear a hole through the timing cover like yours was starting to. i guess 1 way or the other this thing is getting fired off this weekend. can't really drag my feet anymore

Here is my mod I did to my timing cover. http://www.jeepstrokers.com/forum/viewt ... t=aircraft

This was on a 2003 TJ. There wasn't any interference problems with the pin sticking out from the front of the timing chain cover.

The spring and pin may not have had any pressure holding the cam in if your timing cover didn't have the little bump inside. Maybe this is the common link to cam bearing failures? Using a late model timing chain cover ,without the bump, with a spring and pin?

- SilverXJ

- Global Moderator

- Posts: 5790

- Joined: February 14th, 2008, 7:14 am

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

- Location: Radford, Va

Re: Cam bearings failed yet again... please help

My covers have/had the pin.dwg86 wrote: The spring and pin may not have had any pressure holding the cam in if your timing cover didn't have the little bump inside. Maybe this is the common link to cam bearing failures? Using a late model timing chain cover ,without the bump, with a spring and pin?

2000 XJ. 4.6L stroker

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

-

I6FAN

- I made it to triple digits!

- Posts: 172

- Joined: March 28th, 2010, 9:31 am

- Stroker Displacement: 4.2

- Vehicle Year: 1987

- Vehicle Make: jeep

- Vehicle Model: wrangler

Re: Cam bearings failed yet again... please help

Even though you seemingly have good oil pressure, or some, the cam bearings get toasted.doublins wrote:

I had great oil pressure, even with the bearings wiped- 20-25 hot idle, 60-65 hot at speed.

How about the oil pressure relief hole at the rear cam journal. If those get clogged, or blocked, it places positive pressure at the rear of the cam forcing it forward??? Is it possible your lofting the lifters past the oil band? Your cam is way more aggressive[lift] than a stock cam are you sure you have enough spring to keep it stable?

- SilverXJ

- Global Moderator

- Posts: 5790

- Joined: February 14th, 2008, 7:14 am

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

- Location: Radford, Va

Re: Cam bearings failed yet again... please help

I noticed that my oil pressure would drop to 20 then to around 18 after my bearings failed, but that was with a HV oil pump. With good bearings pressure doesn't go below 34 psi.I6FAN wrote:Even though you seemingly have good oil pressure, or some, the cam bearings get toasted.

Good point. Its a fairly large hole, and I doubt it got clogged with such a new engine. However, there is always the possibly that it wasn't drilled from the factory.How about the oil pressure relief hole at the rear cam journal. If those get clogged, or blocked, it places positive pressure at the rear of the cam forcing it forward???

That something to check as well, but I'm betting that isn't a problem as the base circle is probably smaller that stock, which will place the lifter lower in the bore. It is still worth checking, on both the top and bottom of the lifter bore.Is it possible your lofting the lifters past the oil band?

What spring pressures did Bullet cams recommend?Your cam is way more aggressive[lift] than a stock cam are you sure you have enough spring to keep it stable?

2000 XJ. 4.6L stroker

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

- doublins

- I made it to triple digits!

- Posts: 129

- Joined: January 20th, 2010, 11:21 am

- Stroker Displacement: 5.2L V8 (was 4.7L)

- Vehicle Year: 1998

- Vehicle Make: Jeep

- Vehicle Model: Wrangler

- Location: Crofton, MD

Cam surprise... and possible valve train binding...

I've been beating my head against the table trying to figure out why this has happened again. I have been trying to rule out oiling issues, bad cam journals, cam walk, valve train binding, etc etc. I thought I'd completely ruled out the last one as a possibility, but I only realized this morning that the cam I thought I'd had in my engine the whole time is not the one that is actually in there.

I was looking back at the picture I took of the front of my block (attached) when I pulled the timing cover, to see if my block had cast bosses to allow retrofitting an OEM cam retention plate that Jeep started using in 99+ models(It does not), thinking cam walk may have contributed to the loss of the bearings.

Anyway, I noticed that the cam had "Voodoo 63501" stamped on the front journal, which would indicate that I have a Lunati cam in the jeep rather than the Bullet Cam that I'd sent to the machine shop- I do remember at one point the Bullet cam coming back broken in shipping after sending it out for nitriding, but I'd assumed the shop had replaced it with the same cam- but it would seem that what's actually in my motor is a Lunati Voodoo cam #63501- I went ahead and pulled the part number off of Lunati's site, and noticed it has higher gross valve lift values than the Bullet cam I originally had in my motor, and that could be the issue we're seeing with the cam bearings.

The Bullet cam grind was UltraDyne Racing Cams # AM6 266/272-12H (that grind doesn't appear on their master list, but you can get cam card info by calling them- it's also listed on page 1 of this thread)

-It provided a gross valve lift of .471 Intake / .484 Exhaust

The Lunati that's in the block now is 10680701 (cross-references Voodoo #63501)

-it provides a gross valve lift of .484 Intake / .507 Exhaust

The extra .023" of exhaust lift may not be negligible, follow below:

Here's the valve spring information for the build, as provided on my build sheet:

GM Short Block, part number 3911068

O.D. - 1.241"

Installed height - 1.70"

Pressure at installed height - 80# @ 1.70"

Solid Height - 1.15"

Avg. Rate (lbs./in) - 267

80# seat pressure + 267# x (.507 exh valve lift) = 215# open pressure

Open Height = 1.70" installed height - 0.507" gross valve lift = 1.193"

Coil Clearance = 1.193" - 1.15" solid height = 0.043"

From Lunati's website, "a minimum of 0.060" must exist between the coils at maximum lift," which would indicate that while the valvetrain setup was barely adequate for the original cam, it doesn't look like the Lunati would have been able to be swapped in, because the exhaust valves would have been close to binding. Furthermore, i'd have to check with Lunati, but is it possible that that may not have been enough spring to run those lift figures? #80 at the seat, #215 open for .507" lift? The reason the covers got pulled from the motor to begin with is that i was trying to chase a random misfire that seemed to be neither ignition nor fuel related, and now I'm wondering if i may have had some valve float going on too...

What do you guys think?

I was looking back at the picture I took of the front of my block (attached) when I pulled the timing cover, to see if my block had cast bosses to allow retrofitting an OEM cam retention plate that Jeep started using in 99+ models(It does not), thinking cam walk may have contributed to the loss of the bearings.

Anyway, I noticed that the cam had "Voodoo 63501" stamped on the front journal, which would indicate that I have a Lunati cam in the jeep rather than the Bullet Cam that I'd sent to the machine shop- I do remember at one point the Bullet cam coming back broken in shipping after sending it out for nitriding, but I'd assumed the shop had replaced it with the same cam- but it would seem that what's actually in my motor is a Lunati Voodoo cam #63501- I went ahead and pulled the part number off of Lunati's site, and noticed it has higher gross valve lift values than the Bullet cam I originally had in my motor, and that could be the issue we're seeing with the cam bearings.

The Bullet cam grind was UltraDyne Racing Cams # AM6 266/272-12H (that grind doesn't appear on their master list, but you can get cam card info by calling them- it's also listed on page 1 of this thread)

-It provided a gross valve lift of .471 Intake / .484 Exhaust

The Lunati that's in the block now is 10680701 (cross-references Voodoo #63501)

-it provides a gross valve lift of .484 Intake / .507 Exhaust

The extra .023" of exhaust lift may not be negligible, follow below:

Here's the valve spring information for the build, as provided on my build sheet:

GM Short Block, part number 3911068

O.D. - 1.241"

Installed height - 1.70"

Pressure at installed height - 80# @ 1.70"

Solid Height - 1.15"

Avg. Rate (lbs./in) - 267

80# seat pressure + 267# x (.507 exh valve lift) = 215# open pressure

Open Height = 1.70" installed height - 0.507" gross valve lift = 1.193"

Coil Clearance = 1.193" - 1.15" solid height = 0.043"

From Lunati's website, "a minimum of 0.060" must exist between the coils at maximum lift," which would indicate that while the valvetrain setup was barely adequate for the original cam, it doesn't look like the Lunati would have been able to be swapped in, because the exhaust valves would have been close to binding. Furthermore, i'd have to check with Lunati, but is it possible that that may not have been enough spring to run those lift figures? #80 at the seat, #215 open for .507" lift? The reason the covers got pulled from the motor to begin with is that i was trying to chase a random misfire that seemed to be neither ignition nor fuel related, and now I'm wondering if i may have had some valve float going on too...

What do you guys think?

-

6TIME

- Consistent

- Posts: 241

- Joined: October 4th, 2008, 10:53 am

- Stroker Displacement: 4.6

- Vehicle Year: 1993

- Vehicle Make: JEEP

- Vehicle Model: CHEROKEE

Re: Cam bearings failed yet again... please help

I would have the journal surface checked... I had the Voodoo 63500 which wiped my cam bearings out due to journal finish being 3-4x out of spec. I had it micropolished and put new cam bearings back in it's been running great. Do you have any pics of the cam cover marks from the bolt rubbing? Could there be an issue with timing chains causing this walk that we randomly see? Maybe the crank sprocket was cut placing the teeth a bit more forward than the factory location pulling the cam out of the block?

-

CobraMarty

- BANNED

- Posts: 297

- Joined: December 3rd, 2011, 2:01 am

- Vehicle Year: 1998

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

Re: Cam bearings failed yet again... please help

Valve spring coil bind? maybe? Valve float doubt at less than 5000rpm.

1998 XJ 2D AW4 32"MTR 3.55 4.5"RC JCR Slider Magnaflow 150rwHP/174rwTQ=> Sprintex SC Gibson Header 6lb 120-140*IAT 211rwHP/274rwTQ WasherFluid Inj 70mmTB 7.5lb 100-120*IAT=>Now 12 pounds Boost=> +BV ported head

99 XJ M62 S/C

99 XJ M62 S/C

-

jsawduste

- My keyboard is getting warn out

- Posts: 1032

- Joined: February 28th, 2008, 3:13 am

- Stroker Displacement: 4.9

- Location: Michigan

Re: Cam bearings failed yet again... please help

IMHO that is a lot of seat pressure with little to no room for spring flutter and harmonics.

I am critical of the Lunati cams for there very steep ramp angles for our application. Not to mention a history of "rough" journals that extends back to other makes and models of engines.

Journal micro finish is a very important factor that most folks give little regard to. I can recall many instances when developing OEM parts we would experiment with different finishes (smoother means more expensive) and evaluate the wear patterns. This micro finish factor combined with the "longer" overall length of the 6 cylinder cam presents (read as runout over it`s length) a perfect scenario for bearing failure. The cam has to be round, flat, square, polished and uniform. Missing any one of these factors is critical.

Chamfering the cam bearing oiling holes is another critical attention to detail procedure that should be done with any OHV engine.

I am critical of the Lunati cams for there very steep ramp angles for our application. Not to mention a history of "rough" journals that extends back to other makes and models of engines.

Journal micro finish is a very important factor that most folks give little regard to. I can recall many instances when developing OEM parts we would experiment with different finishes (smoother means more expensive) and evaluate the wear patterns. This micro finish factor combined with the "longer" overall length of the 6 cylinder cam presents (read as runout over it`s length) a perfect scenario for bearing failure. The cam has to be round, flat, square, polished and uniform. Missing any one of these factors is critical.

Chamfering the cam bearing oiling holes is another critical attention to detail procedure that should be done with any OHV engine.

-

6TIME

- Consistent

- Posts: 241

- Joined: October 4th, 2008, 10:53 am

- Stroker Displacement: 4.6

- Vehicle Year: 1993

- Vehicle Make: JEEP

- Vehicle Model: CHEROKEE

Re: Cam bearings failed yet again... please help

From my experiences in running the Lunati Voodoo and 2 Comps in the 4.0/4.6 platform and i'd have to say that the Comp 231/232 etc.. are definitely more aggressive than Lunati's profiles. The Comp grinds sounded like sewing machines while driving above 1500rpm. They made good power but a bit on the noisy side. The Lunati had more lift but was still almost silent in comparison.jsawduste wrote:IMHO that is a lot of seat pressure with little to no room for spring flutter and harmonics.

I am critical of the Lunati cams for there very steep ramp angles for our application. Not to mention a history of "rough" journals that extends back to other makes and models of engines.

Journal micro finish is a very important factor that most folks give little regard to. I can recall many instances when developing OEM parts we would experiment with different finishes (smoother means more expensive) and evaluate the wear patterns. This micro finish factor combined with the "longer" overall length of the 6 cylinder cam presents (read as runout over it`s length) a perfect scenario for bearing failure. The cam has to be round, flat, square, polished and uniform. Missing any one of these factors is critical.

Chamfering the cam bearing oiling holes is another critical attention to detail procedure that should be done with any OHV engine.

X2! "Longer" but with only 4 journals to put even more pressure on the bearings. And not to mention, a majority of the V-8's out there have 5 cam journals along with a substantially shorter length. Probably why we don't hear of this type of failure very often.jsawduste wrote:This micro finish factor combined with the "longer" overall length of the 6 cylinder cam presents (read as runout over it`s length) a perfect scenario for bearing failure. The cam has to be round, flat, square, polished and uniform. Missing any one of these factors is critical.

I'll post these pics of my lessons learned in hope that guys might reduce their chances of wiping out a set of cam bearings.

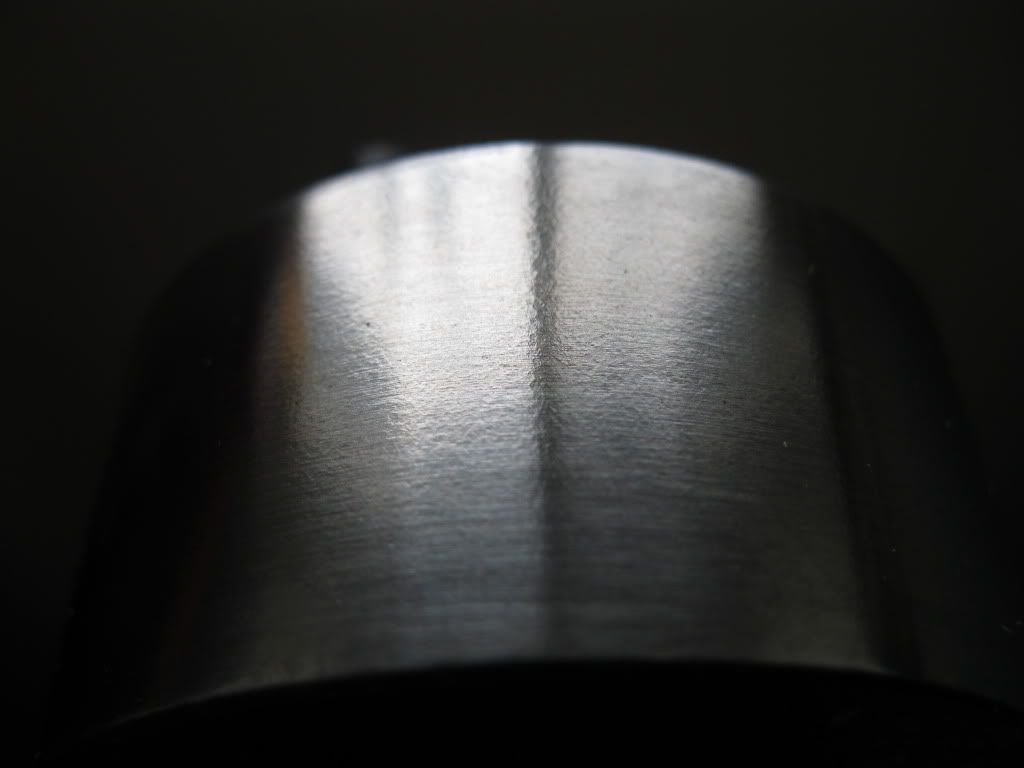

Look familiar?

New Lunati Voodoo at a glance, looks like a new cam .....

Journal up close, not lookin so smooth anymore...more like 400grit. This will gobble up bearings for lunch.

For comparison: Factory GM roller cam polished to last the life of an engine.....

This is what every journal should look like in a reliable setup!

Keep in mind... from what I've learned, this surface finish issue is not only specific to Lunati. My machinist said "most" aftermarket cams have an inferior journal finish because the journals are typically machined and polished at the foundry then shipped to the cam company to have the dist. gears and lobes cut. Depending on how these companies handle the cam cores thru the process will determine how long the journals will get the buffing wheel treatment which eventually creates this rough orange peely pattern as seen on the Lunati. Sounds like you can order two cams from the same company, and get a winner and a loser depending on who handled the core that particular day....When in doubt, spend a few extra bucks and have them polished!

- doublins

- I made it to triple digits!

- Posts: 129

- Joined: January 20th, 2010, 11:21 am

- Stroker Displacement: 5.2L V8 (was 4.7L)

- Vehicle Year: 1998

- Vehicle Make: Jeep

- Vehicle Model: Wrangler

- Location: Crofton, MD

Re: Cam bearings failed yet again... please help

Regarding my concerns over coil bind and spring rates/valve float- I called Lunati today, and they were fine with the seat pressure/spring rate for the application, and were not convinced about coil bind wiping the bearing- they say that would have likely manifested itself in other ways, i.e. wiped lobes before wiped bearings. They also claim people routinely run rollers on babbit bearings with hundreds of pounds of seat pressure and that it takes a LOT of load to mess up cam bearings, as they are supposedly extremely durable (assuming correct install, no damage, cam not too tight, etc).

I'm really intrigued about those rough cam journal pics, I am looking forward to the disassembly of the motor and the visual inspection of the cam & bearings, and what the shop's verdict is...

So, there will be nothing new to report until the shop breaks the motor down and renders it's opinion on what happened. I'll report back then.

Thank you guys so far for helping to try to diagnose, stay tuned.

I'm really intrigued about those rough cam journal pics, I am looking forward to the disassembly of the motor and the visual inspection of the cam & bearings, and what the shop's verdict is...

So, there will be nothing new to report until the shop breaks the motor down and renders it's opinion on what happened. I'll report back then.

Thank you guys so far for helping to try to diagnose, stay tuned.

- SilverXJ

- Global Moderator

- Posts: 5790

- Joined: February 14th, 2008, 7:14 am

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

- Location: Radford, Va

Re: Cam bearings failed yet again... please help

That had been my experience as well, but usually between 1500-2500 RPM. After that it either went away or couldn't hear it over the engine. It was just there at a partial load.6TIME wrote: The Comp grinds sounded like sewing machines while driving above 1500rpm. They made good power but a bit on the noisy side.

Those journals look awful. I wish that had been my problem though. None of the cams I have ran had looked like that.I'll post these pics of my lessons learned in hope that guys might reduce their chances of wiping out a set of cam bearings.

I don't agree about their assessment that coil bind (or other bind) couldn't wipe out bearing. I see that as a possibility. While it is true that much heavier springs are run with babbit bearings, binding or solid would shoot the "spring rate" the cam sees through the roof.doublins wrote:and were not convinced about coil bind wiping the bearing- they say that would have likely manifested itself in other ways, i.e. wiped lobes before wiped bearings. They also claim people routinely run rollers on babbit bearings with hundreds of pounds of seat pressure and that it takes a LOT of load to mess up cam bearings, as they are supposedly extremely durable (assuming correct install, no damage, cam not too tight, etc).

2000 XJ. 4.6L stroker

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

-

jsawduste

- My keyboard is getting warn out

- Posts: 1032

- Joined: February 28th, 2008, 3:13 am

- Stroker Displacement: 4.9

- Location: Michigan

Re: Cam bearings failed yet again... please help

If the journals are properly finished to the BEARING MAKERS spec. and the cam is flat and square. Their own specs call for a greater amount of spring clearance then you ran.doublins wrote:Regarding my concerns over coil bind and spring rates/valve float- I called Lunati today, and they were fine with the seat pressure/spring rate for the application, and were not convinced about coil bind wiping the bearing- they say that would have likely manifested itself in other ways, i.e. wiped lobes before wiped bearings. They also claim people routinely run rollers on babbit bearings with hundreds of pounds of seat pressure and that it takes a LOT of load to mess up cam bearings, as they are supposedly extremely durable (assuming correct install, no damage, cam not too tight, etc).

As you mentioned it will be interesting to put the cam on an inspection table and evaluate the journal finish and the the overall squareness of the cam itself. Not to mention the block itself.

I had mine line honed much in the same way you do a set of mains. We went through two Hesco cams till we found one that met our specs. prior to installation.

I would also suggest the chamfering of the new bearings.

Comp or Lunati. i still personally feel the Lunati ramps are too steep. Just MHO.

Who is online

Users browsing this forum: No registered users and 2 guests