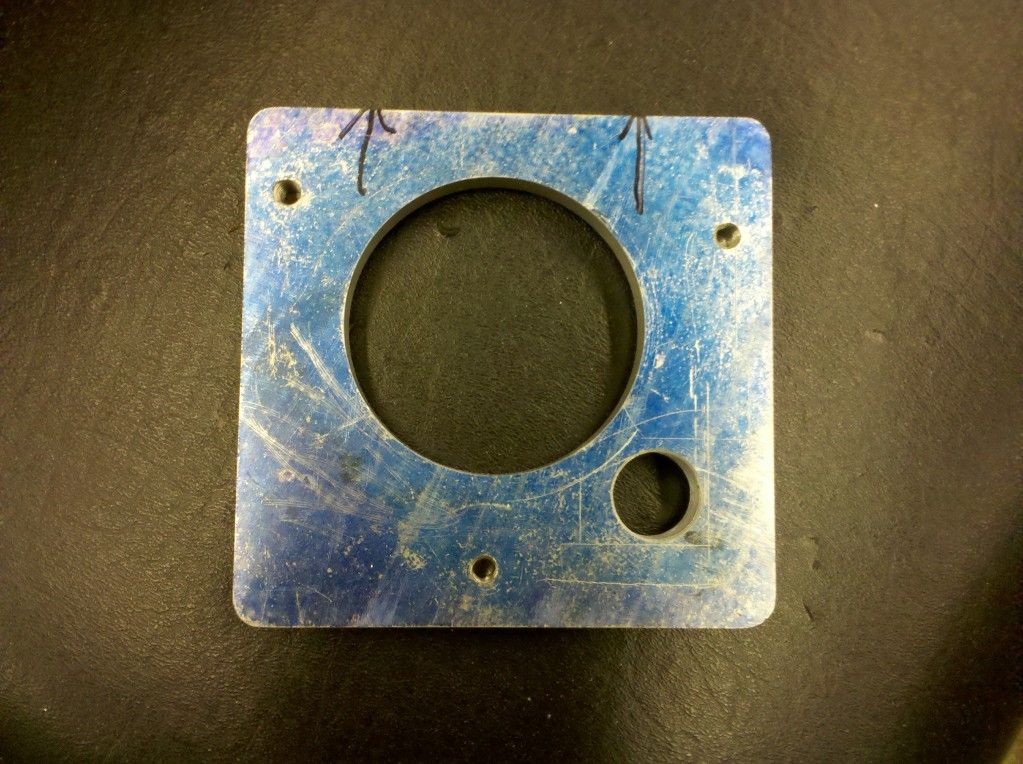

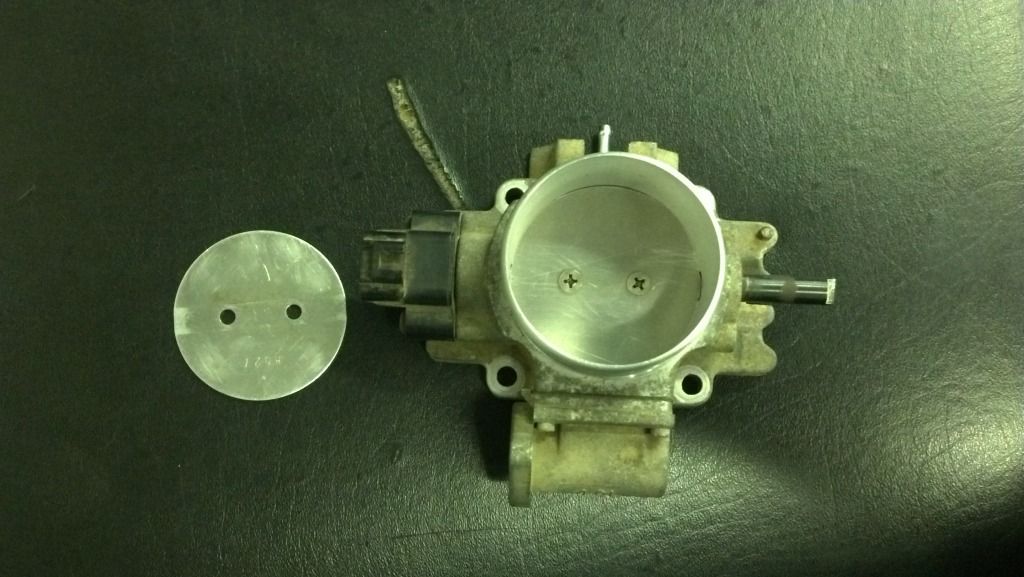

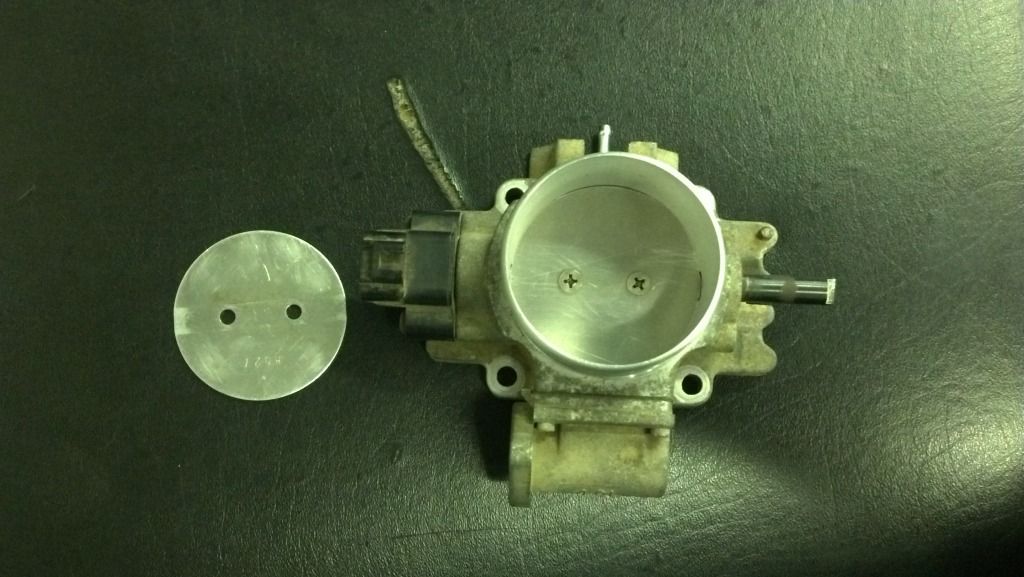

So the next big dilemma with the throttle Body is the throttle blade, when closed, it sits at ~10* angle inside the bore. This angle is critical for about 100 reasons but the top two that come to mind are TPS voltage and the shaft arm. My universal scan tool doesn't read voltage for whatever reason but it does read percentage, so whatever, a number is a number. The stocker registered "14.7%" at idle. The shaft arm needed to end up at the same angle so the setscrew/stop would function properly. Sure theres adjustment but not much. Ok, enough of the reasons, how do you plug a round hole at an angle? With an oval! I don't have any pics of the fixture i made to make the blades but ill describe it as best as possible. Its a 3x3x1 block with an angle (10*) cut in it. Horizontally, in the center of that angle i drilled and tapped to 8-32 holes. These were so i could bolt a 3x3 sheet to the fixture for milling. The sheets then went in a mill to have the holes/countersinks placed in them. I need to get a pic of them as well. Anyhow, with the plate at an angle, i milled a 2.500" circle vertically around the center. Viola! The TB shaft had to be heavily modified, which you can kinda see, but the long and short is, I cut the top of the slot off and widened "seating" area. Locktight is a must here! On the the pics:

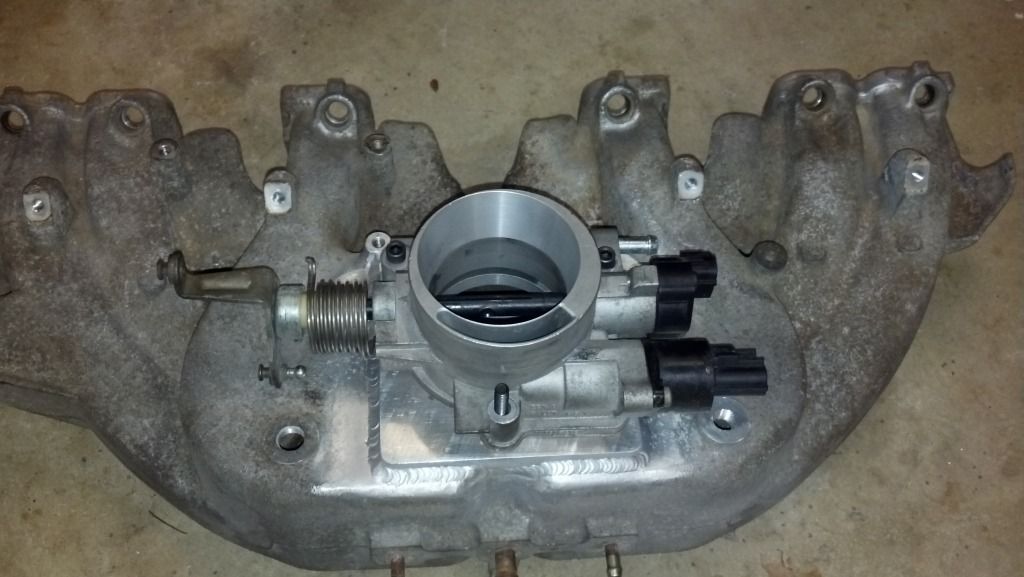

Assembled on a spare shaft:

Old inside of new:

All in all the new blade seated well but did require some finish filing to be perfect. With the TB finish assembled, I hooked up my scan tool and plugged in only the TPS to the new body. I wanted to confirm that the closed reading was right/acceptable. NOTE: 15.1% is REAL close to 14.7% but not the same. I fired up the motor too confirm idle as seen in the pic below but the sensor reading was off just the tiniest C-hair.

For those of you that don't know how the TPS(Throttle Postion) and Idle air circuit operates; when the blade is closed(confirmed by the sensor reading) the Idle air motor opens and closes to control idle. When you come off idle, even the slightest, the TPS registers the blade is open, the computer will fully open the IAC(Idle Air Control). The computer confirms the airflow increase using the MAP(Manifold Absolute Pressure). If it cannot confirm whats going on, it will surge. Well, 15.1% is enough to cause surge. I loosened the TPS screws to see if i could wiggle it enough be happy but, nope, it wasn't having that. Now what!? I have about 30 TPS's (throttle body hoarding is a thing i have/do; dont hate!) so i modified one by pushing/spinning out the sleeves using a vise and ~.200" drill. The idea was to use a large enough drill, not to cut the sleeves but get them stuck on the drill so i could spin them out. As seen below:

This is what was needed. I got the TPS reading to 14.7% and tightened down the screws using serrated washers to keep everything stationary. I started the jeep, as seen below, and let it idle through quite a few heat cycles just to be sure it knew how how to idle. I blipped the throttle as well to confirm its ability to come back down, a few times.

Finished product idling:

Said TJ:

I tune my jeep using a DTEC controller, made by TurboXS. It modifies the MAP sensor reading according to a scale written using a GameBoyDS. I use an Innovate Motorsport Wideband to confirm my adjustments. Some info on my motor: 4.7ltr using .060" KB944's, Blueprinted and balanced, shotpeened/sanded/polished 4.0 rods, .005 deck, polished combustion chamber, TurboToms old 0331 head w/ LS1 2.02/1.57 SS valves and a svelte Port job, 24lbs injectors, 30ab cam adv 4*, ported WJ manifold, stock Tj header/2.5" exhaust. Ok, so the motor has been real torque pig up to 3K taking a huge crap thereafter. I believe this is partly the TB and mostly my decision to advance the cam

. Hind sight is always 20/20. With this new TB airflow increased a good bit from off-idle to 4k warranting a 5% increase(disclaimer:

according to my DTEC) in fuel from 0-3k and a 7-9% increase from 3-4K. It still craps the bed past 4K

. BTW, i aim for 12:1 with NA motors and 10.5-11.5 with forced induction. Im still not 100% happy with the end result as id like it to pull harder past 4K but i think i have a few hurdles in the way i'll cover later.

My goal with this project (and thread) was to fix an airflow issue (which it did, kinda), log it somewhere so others/I could review it, hopefully inspire others to do this mod on there own. I will hopefully get all my pics together from my motor build and start a build thread soon. Id like to, also, document the changes that come from cam timing adjustments. Im also looking for input from those who know the 30ab cam first hand. Where did you set yours? Why? How do you like it?

4.7 Stroker, AW4, Dana 60, 14Bolt, AtlasII 4.3, 104"Wb, 40" Nittos on Walker Evans