crank bearing brace

-

dzrtrataz

- Posts: 6

- Joined: March 27th, 2011, 8:36 am

- Vehicle Year: 1987

- Vehicle Make: Jeep

- Vehicle Model: YJ

crank bearing brace

If I decide to use the main bearing brace. What should be the clearance between the piston rods and the brace.

Thanks

Thanks

- Missourian

- Donator

- Posts: 142

- Joined: July 5th, 2011, 3:51 pm

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Wrangler

- Location: K.C. Metro Area

- Contact:

Re: crank bearing brace

Based upon what I've read and images shown on various STROKER threads /sites, that is to be two flat washers stacked to provide proper clearance.

-

5-90

- I made it to triple digits!

- Posts: 163

- Joined: February 19th, 2008, 9:16 pm

- Location: Hammerspace

- Contact:

Re: crank bearing brace

0.100" to 0.200" should be plenty to allow for material stretch - two flat washers is about right for absolute minimum clearance.dzrtrataz wrote:If I decide to use the main bearing brace. What should be the clearance between the piston rods and the brace.

Thanks

Are you retrofitting one, or fabricating one?

Kelley's Works in Progress - http://www.kelleyswip.com

KWiP Parts Exchange - http://www.kelleyswip.com/exchange.html

"I don't think any of us will ever forget Louie. Ever since the explosion, there's been a little piece of him on all of us..."

KWiP Parts Exchange - http://www.kelleyswip.com/exchange.html

"I don't think any of us will ever forget Louie. Ever since the explosion, there's been a little piece of him on all of us..."

-

dzrtrataz

- Posts: 6

- Joined: March 27th, 2011, 8:36 am

- Vehicle Year: 1987

- Vehicle Make: Jeep

- Vehicle Model: YJ

Re: crank bearing brace

The motor I'm using is from a 98 and already had it. So figured I use it since I have it. So I guess I will get some washers in the morning.

Thanks

Thanks

-

btownxj

- Posts: 1

- Joined: October 11th, 2011, 1:53 pm

- Vehicle Year: 1992

- Vehicle Make: jeep

- Vehicle Model: cherokee

Re: crank bearing brace

sorry to steal the thread but im new here. i have a 92 block and is the main bearing brace a swap besides changing the main bolts and stacking the washers? thanks!

-

SIXPAK

- Consistent

- Posts: 218

- Joined: March 8th, 2008, 5:34 am

- Stroker Displacement: 280

Re: crank bearing brace

Correct btownxj.

QUESTION...

Not sure about this guys but are the later 4.0 oil pans a bit deeper to allow for the brace or are the pans the same? I DO know that if you use a 258 deep sump pan (and the corresponding pickup for the pump) the brace hits the pan you have to relief it with a BFH a bit.

QUESTION...

Not sure about this guys but are the later 4.0 oil pans a bit deeper to allow for the brace or are the pans the same? I DO know that if you use a 258 deep sump pan (and the corresponding pickup for the pump) the brace hits the pan you have to relief it with a BFH a bit.

- SilverXJ

- Global Moderator

- Posts: 5790

- Joined: February 14th, 2008, 7:14 am

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

- Location: Radford, Va

Re: crank bearing brace

They aren't. And the fit varies between pan. I had to massage my pan a bit to get it to fit with the spaced out girdle, particularly at the front.

2000 XJ. 4.6L stroker

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

-

SIXPAK

- Consistent

- Posts: 218

- Joined: March 8th, 2008, 5:34 am

- Stroker Displacement: 280

Re: crank bearing brace

On the front of a 4.0 pan SilverXJ?

- SilverXJ

- Global Moderator

- Posts: 5790

- Joined: February 14th, 2008, 7:14 am

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

- Location: Radford, Va

Re: crank bearing brace

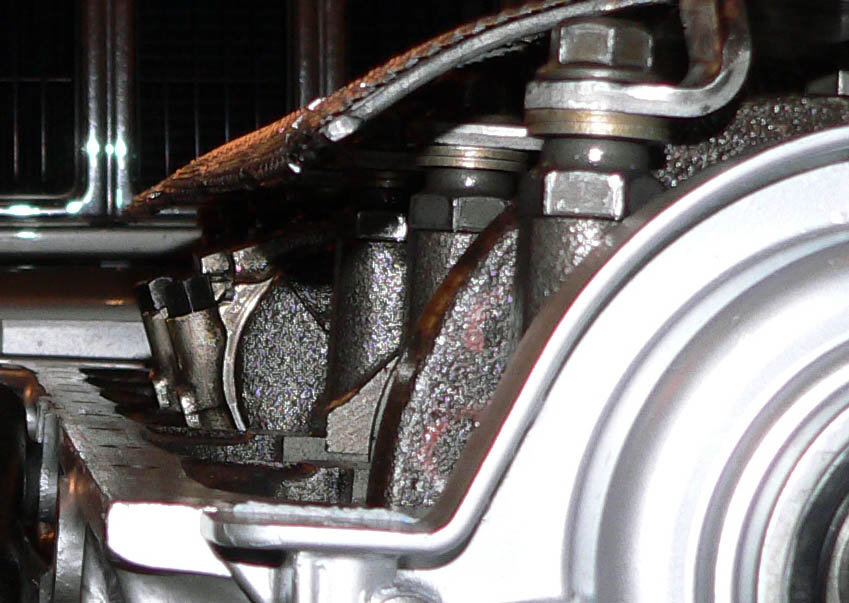

Yes, where it starts to curve up. That is where most of the bending was. IIRC someone on here has an image of where he heated it up bent the pan that way.

2000 XJ. 4.6L stroker

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

-

SIXPAK

- Consistent

- Posts: 218

- Joined: March 8th, 2008, 5:34 am

- Stroker Displacement: 280

Re: crank bearing brace

Wow, would have not guessed that one. But then again I have never compared the two pans side by side either.

-

Desertjr

- BANNED

- Posts: 159

- Joined: December 31st, 2012, 2:12 am

- Vehicle Year: 1990

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

Re: crank bearing brace

Bumping this as well vs creating new. Picked up a running 98 motor for 100 bucks  ill be using the head on it and was curious about grabbing main girdle and using it in my 88 block? Outside of making sure there's clearence its bolt on and go right?

ill be using the head on it and was curious about grabbing main girdle and using it in my 88 block? Outside of making sure there's clearence its bolt on and go right?

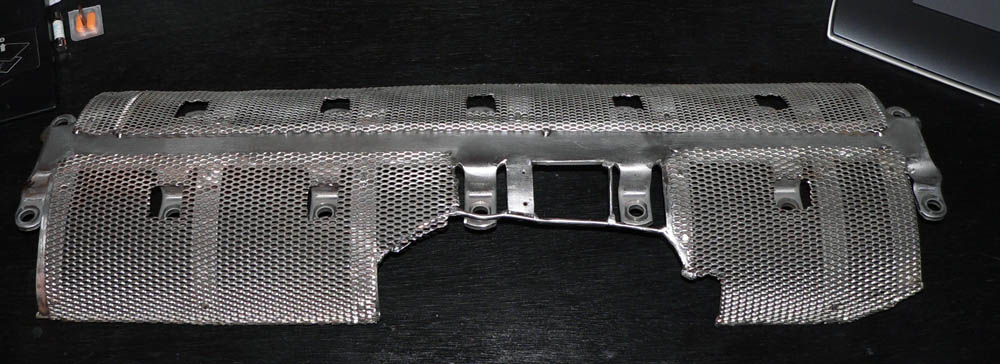

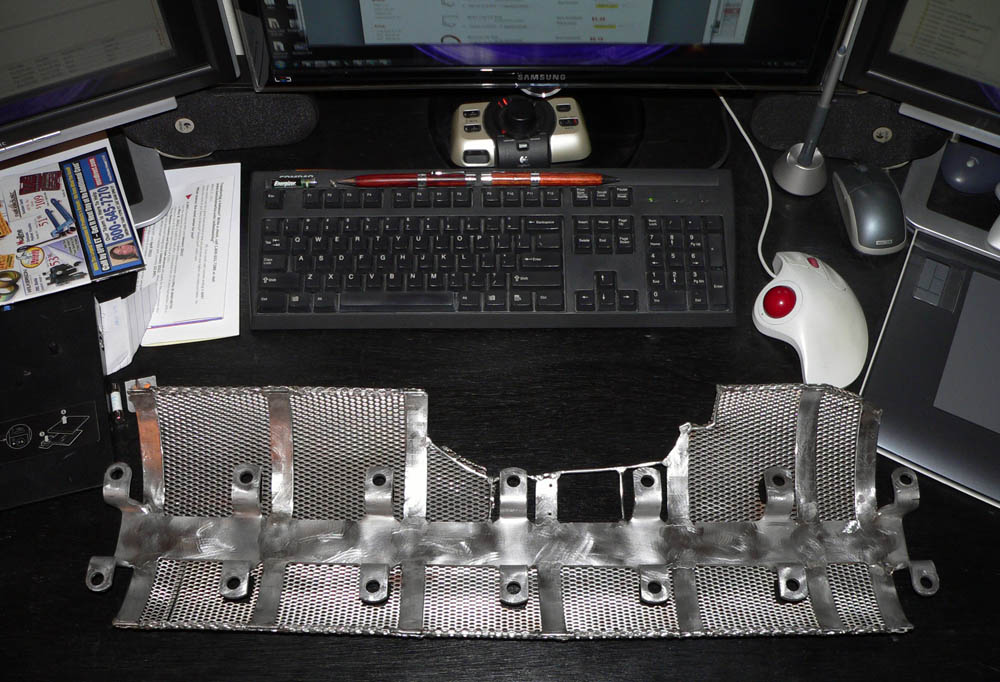

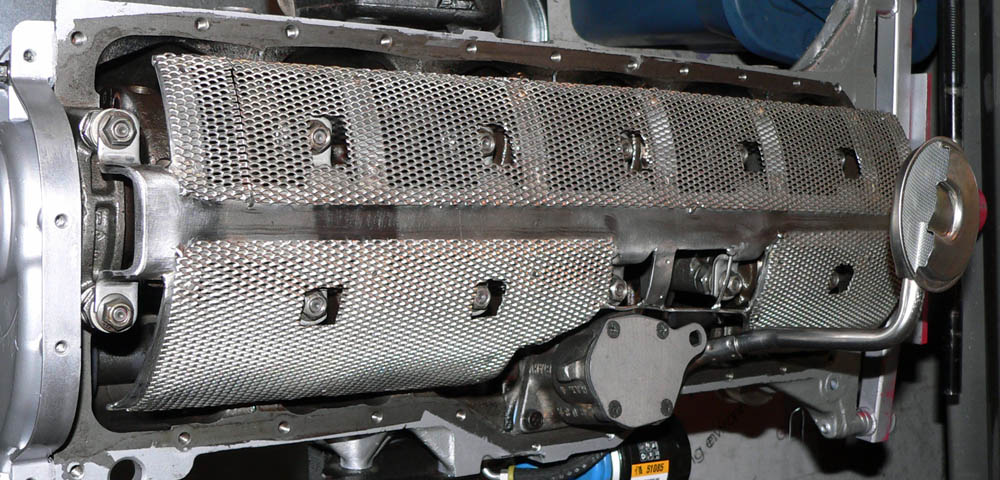

Also Chris? Silverxj..can you host those pics of your windage screen you did off the girdle?

Also Chris? Silverxj..can you host those pics of your windage screen you did off the girdle?

- SilverXJ

- Global Moderator

- Posts: 5790

- Joined: February 14th, 2008, 7:14 am

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

- Location: Radford, Va

Re: crank bearing brace

Using the girdle should be fine on your 88. Just check to see if where the main cap bolts hit the main cap are in line with each other. Yes, space the girdle up with some washers.

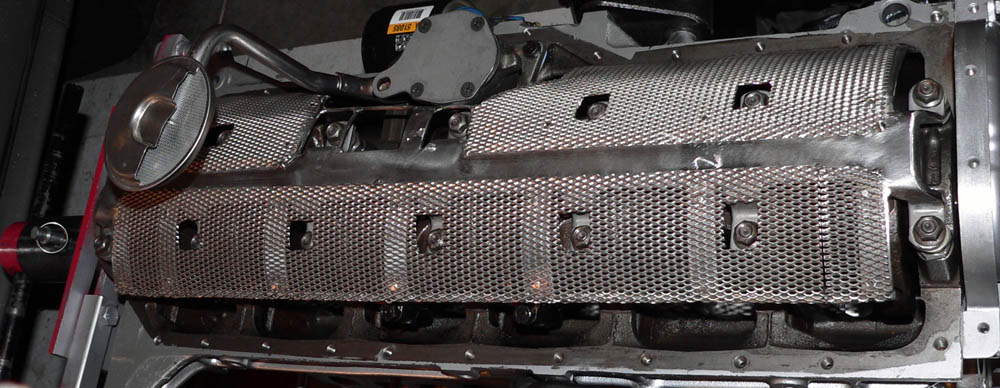

The images are in the build thread. http://www.jeepstrokers.com/forum/viewt ... 40&p=23474 But I'll put them here too.

The images are in the build thread. http://www.jeepstrokers.com/forum/viewt ... 40&p=23474 But I'll put them here too.

2000 XJ. 4.6L stroker

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

-

Desertjr

- BANNED

- Posts: 159

- Joined: December 31st, 2012, 2:12 am

- Vehicle Year: 1990

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

Re: crank bearing brace

Look like some 1/8"x1" wide strap? And some expanded metal? Would you do anything differently if you could do it a 2nd time?

- SilverXJ

- Global Moderator

- Posts: 5790

- Joined: February 14th, 2008, 7:14 am

- Stroker Displacement: 4.6L

- Vehicle Year: 2000

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

- Location: Radford, Va

Re: crank bearing brace

Yes, its 1/8" x 1", might be 3/4" can't recall. It is a form of expanded steel, but they are more like small directional louvers. I want to say its a Morso screen.

2000 XJ. 4.6L stroker

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

00+ Viper Coil Swap | CPS Timing Increase Mod | Fabricated Airbox | Dash bezel, Arduino Multigauge & RD Conceal

Eat, breath, drink, sleep, Jeep, drink

-

Desertjr

- BANNED

- Posts: 159

- Joined: December 31st, 2012, 2:12 am

- Vehicle Year: 1990

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

Re: crank bearing brace

SilverXJ wrote:Yes, its 1/8" x 1", might be 3/4" can't recall. It is a form of expanded steel, but they are more like small directional louvers. I want to say its a Morso screen.

Alrighty. Looks like the stuff that's on my satellite in the back yard...the fiancé would kill me

How did you connect it all? I know you formed and welded the strap. I think I see a few tacks but it almost looks rolled at the edges? Am I seeing rivets?

Would you do it another way if you could?

Who is online

Users browsing this forum: No registered users and 3 guests