The scans are on the to-do pile, along with everything else.

4.0 head and EFI on a 4.2 block

- Jeep-Power

- Donator

- Posts: 182

- Joined: February 13th, 2008, 7:32 pm

- Stroker Displacement: 4.3

- Vehicle Year: 1984

- Vehicle Make: AMC/Jeep

- Vehicle Model: CJ-7

- Location: Fort Mill, SC

Re: 4.0 head and EFI on a 4.2 block

Yeah-- I wasn't too happy about it. To HESCO's credit-- they did give me a break on the replacement.

The scans are on the to-do pile, along with everything else.

The scans are on the to-do pile, along with everything else.

-- TallPeter

'84 CJ-7 - tonned & turbo'd

'84 CJ-7 - tonned & turbo'd

- DOUG

- Posts: 3

- Joined: May 12th, 2008, 4:13 am

- Vehicle Year: 1981

- Vehicle Make: Jeep

- Vehicle Model: CJ-8

- Location: Haverhill, Ma.

Re: 4.0 head and EFI on a 4.2 block

I have read and reread this thread a 1/2 dozen times and I'm ready to take the plunge. Swapping a 4.0 head/efi onto the 258 in my Scrambler.

I'll be sending the head to the machine shop this week, then to purchase the needed parts to complete the install.

I'll be sending the head to the machine shop this week, then to purchase the needed parts to complete the install.

1981 CJ-8 258 NV4500 D300

- DOUG

- Posts: 3

- Joined: May 12th, 2008, 4:13 am

- Vehicle Year: 1981

- Vehicle Make: Jeep

- Vehicle Model: CJ-8

- Location: Haverhill, Ma.

Re: 4.0 head and EFI on a 4.2 block

Forgot to ask a question...which motor was the gasket set and new pushrods bought for? (or maybe they are the same P/Ns?)

1981 CJ-8 258 NV4500 D300

- Jeep-Power

- Donator

- Posts: 182

- Joined: February 13th, 2008, 7:32 pm

- Stroker Displacement: 4.3

- Vehicle Year: 1984

- Vehicle Make: AMC/Jeep

- Vehicle Model: CJ-7

- Location: Fort Mill, SC

Re: 4.0 head and EFI on a 4.2 block

Doug-

Buy a head gasket for the model/year head you have.

As far as I know, the 4.2 & 4.0 share the identical pushrods. On the first head swap I

did, 4.2 push-rods were used (because I had them). On Toms' swap, 4.0 rods were used.

While on topic: On the first head swap, 4.2 rockers, bridges, etc were used on the 4.0 head. They are interchangeable.

Buy a head gasket for the model/year head you have.

As far as I know, the 4.2 & 4.0 share the identical pushrods. On the first head swap I

did, 4.2 push-rods were used (because I had them). On Toms' swap, 4.0 rods were used.

While on topic: On the first head swap, 4.2 rockers, bridges, etc were used on the 4.0 head. They are interchangeable.

-- TallPeter

'84 CJ-7 - tonned & turbo'd

'84 CJ-7 - tonned & turbo'd

-

akecj7

- Posts: 3

- Joined: October 4th, 2010, 2:41 pm

- Vehicle Year: 1984

- Vehicle Make: Jeep

- Vehicle Model: CJ7

Re: 4.0 head and EFI on a 4.2 block

Have you had any drivabiliy issues using the stock PCM? I posted over at hesco and they said there are issue when using a stock computer with the conversion. Thanks for the help and exellent thread.

- Jeep-Power

- Donator

- Posts: 182

- Joined: February 13th, 2008, 7:32 pm

- Stroker Displacement: 4.3

- Vehicle Year: 1984

- Vehicle Make: AMC/Jeep

- Vehicle Model: CJ-7

- Location: Fort Mill, SC

Re: 4.0 head and EFI on a 4.2 block

curious.

That's all I've used. No issues. They work fine, for me.

What issues did they describe?

That's all I've used. No issues. They work fine, for me.

What issues did they describe?

-- TallPeter

'84 CJ-7 - tonned & turbo'd

'84 CJ-7 - tonned & turbo'd

-

akecj7

- Posts: 3

- Joined: October 4th, 2010, 2:41 pm

- Vehicle Year: 1984

- Vehicle Make: Jeep

- Vehicle Model: CJ7

Re: 4.0 head and EFI on a 4.2 block

Jeep-Power wrote:curious.

That's all I've used. No issues. They work fine, for me.

What issues did they describe?

This is what LEEE said on the Hesco forum

"The main thing is all the codes that cause drive ability problems have been eliminated. The timing curves are set for performance, the fuel window is wider for compatibility."

As far as what causes issue not sure. How many conversion have you done? Are you a PCM from an automatic or a manual? I will be running a th400 with a reverse pattern manual valve body. If useing a stock computer works that would same me a bunch of money which will help get my heep back on the road. Thanks for the help.

- Jeep-Power

- Donator

- Posts: 182

- Joined: February 13th, 2008, 7:32 pm

- Stroker Displacement: 4.3

- Vehicle Year: 1984

- Vehicle Make: AMC/Jeep

- Vehicle Model: CJ-7

- Location: Fort Mill, SC

Re: 4.0 head and EFI on a 4.2 block

I've done two conversions.

They were both initially run with automatic PCM's on manual transmission Jeeps.

I have since picked up a second computer for mine (backup) and have switched it in & out numerous times. They all work fine.

I am sure HESCO's computer works better than the OEM setup, but I'm VERY happy with the junkyard PCM's we've used.

They were both initially run with automatic PCM's on manual transmission Jeeps.

I have since picked up a second computer for mine (backup) and have switched it in & out numerous times. They all work fine.

I am sure HESCO's computer works better than the OEM setup, but I'm VERY happy with the junkyard PCM's we've used.

-- TallPeter

'84 CJ-7 - tonned & turbo'd

'84 CJ-7 - tonned & turbo'd

-

akecj7

- Posts: 3

- Joined: October 4th, 2010, 2:41 pm

- Vehicle Year: 1984

- Vehicle Make: Jeep

- Vehicle Model: CJ7

Re: 4.0 head and EFI on a 4.2 block

Thanks good to know. This saves me about 300 bucks. Thanks again for the help.

-

fivestring

- Posts: 7

- Joined: August 29th, 2010, 5:26 am

- Vehicle Year: 1990

- Vehicle Make: Jeep

- Vehicle Model: Wrangler

Re: 4.0 head and EFI on a 4.2 block

I found a big difference between the 4.2 (not sure of year, possibly a 1990) and 4.0 (1996) pushrods. I measured spring preload and it was over 1/4" with the 4.0 rods. The 4.2 rods were significantly shorter ( I forget the measured difference and the spring preload measurement on these) but I ended up using the shorter ones and the Jeep runs fine.

I am running an OBDII system. I need to know if the ecm is supposed to have a 12v supply that is always on so it can retain the learned info. I feel the motor is relearning settings every time I fire it up. It starts rough like there is a big cam in it, then after 30 seconds or so it settles into a smooth idle.

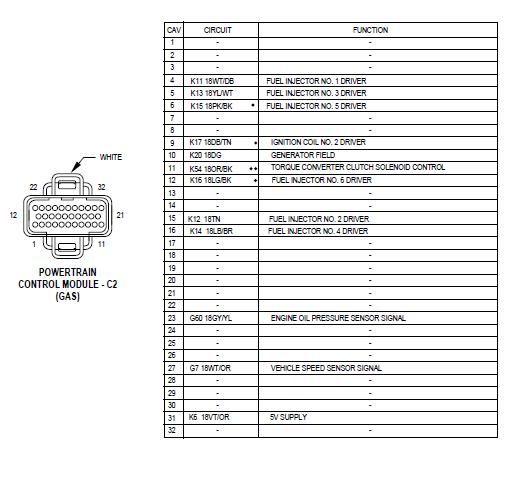

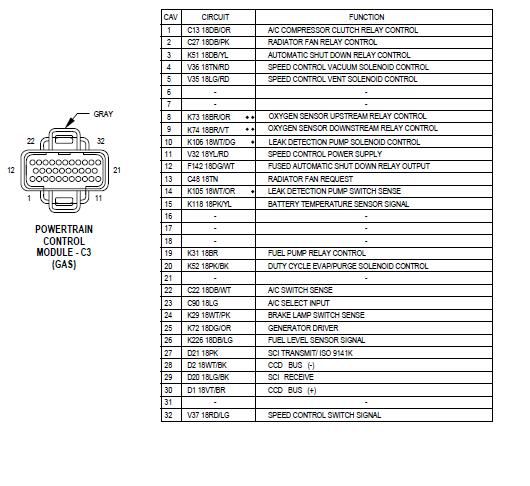

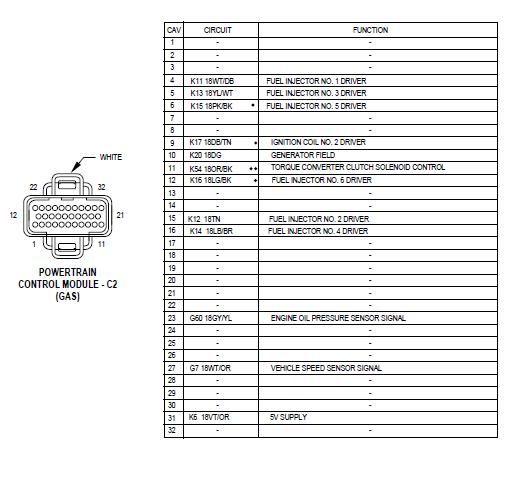

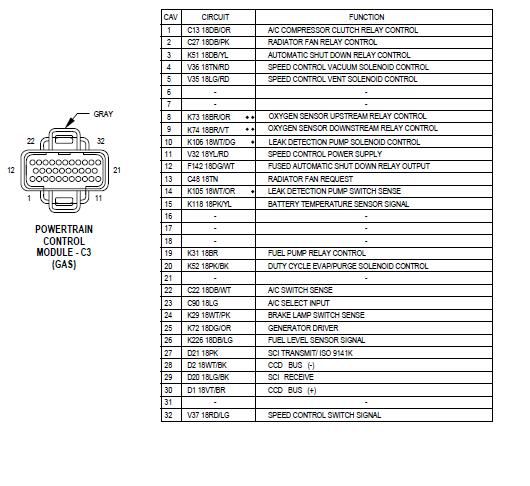

If the ecm is supposed to have a non-interrupted 12v supply, which wire would it be? I have posted the pinout for these computers here:

http://www.jeepforum.com/forum/f12/newe ... e-1111789/

I am running an OBDII system. I need to know if the ecm is supposed to have a 12v supply that is always on so it can retain the learned info. I feel the motor is relearning settings every time I fire it up. It starts rough like there is a big cam in it, then after 30 seconds or so it settles into a smooth idle.

If the ecm is supposed to have a non-interrupted 12v supply, which wire would it be? I have posted the pinout for these computers here:

http://www.jeepforum.com/forum/f12/newe ... e-1111789/

I am dyslexic but I am also cross-eyed so I can read perfectly well.

- Jeep-Power

- Donator

- Posts: 182

- Joined: February 13th, 2008, 7:32 pm

- Stroker Displacement: 4.3

- Vehicle Year: 1984

- Vehicle Make: AMC/Jeep

- Vehicle Model: CJ-7

- Location: Fort Mill, SC

Re: 4.0 head and EFI on a 4.2 block

fivestring-

Yeah-- I'm not sure of the years/pushrod specs. I did measure the ones I had in my 4.2 against the ones that came out of the donor 4.0 OBD1 engine-- they were visibly (I didn't use a micrometer or anything) the same exact size.

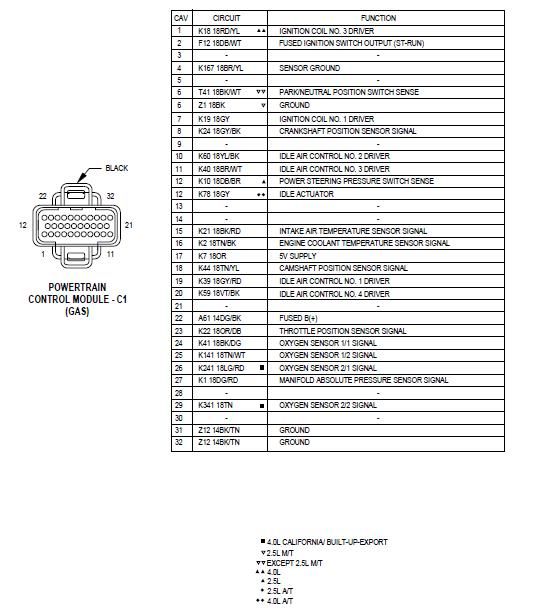

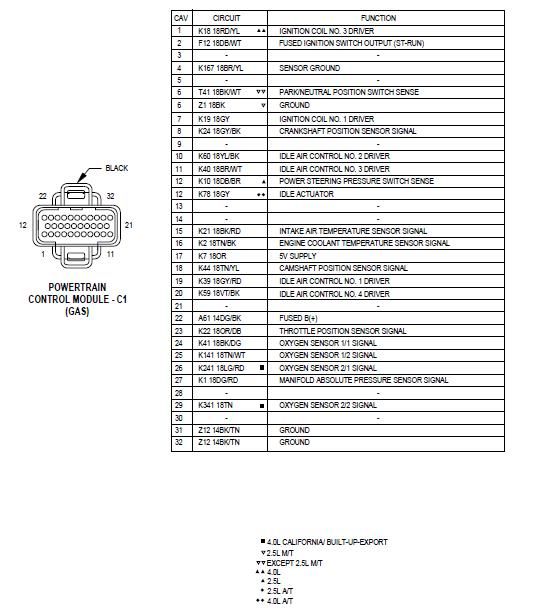

It looks like:

pin #22 is for Fused battery-- constant 12V supply.

pin #2 is fused ignition (switched) positive 12V.

pin #6 is ground

Yeah-- I'm not sure of the years/pushrod specs. I did measure the ones I had in my 4.2 against the ones that came out of the donor 4.0 OBD1 engine-- they were visibly (I didn't use a micrometer or anything) the same exact size.

It looks like:

pin #22 is for Fused battery-- constant 12V supply.

pin #2 is fused ignition (switched) positive 12V.

pin #6 is ground

-- TallPeter

'84 CJ-7 - tonned & turbo'd

'84 CJ-7 - tonned & turbo'd

-

fivestring

- Posts: 7

- Joined: August 29th, 2010, 5:26 am

- Vehicle Year: 1990

- Vehicle Make: Jeep

- Vehicle Model: Wrangler

Re: 4.0 head and EFI on a 4.2 block

Thanks for the confirmation Jeep Power. I suspected number 22 was the rascal I was lookng for. I will test to see if it's getting 12v when the key is off.

I am dyslexic but I am also cross-eyed so I can read perfectly well.

-

fivestring

- Posts: 7

- Joined: August 29th, 2010, 5:26 am

- Vehicle Year: 1990

- Vehicle Make: Jeep

- Vehicle Model: Wrangler

Re: 4.0 head and EFI on a 4.2 block

I just checked that wire and I am getting 12v there all the time. I think my rough initial idle may be related to a fuel pressure leakdown issue I am having. The pressure bleeds off to around 25lbs within about 30 minutes

Does anyone know how to shim the regulators to adjust fuel pressure? I have heard you can do this easily as opposed to buying an adjustable regulator.

I am using the '96 fuel pump which has a built-in regulator on the pump but my fuel rail also has a regulator on it so it is not original with this '96 motor. Right now the return line is plugged as you don't run one with the '96 systems.

I am thinking of going with a Ford truck external pump to get the 49 lbs of pressure needed and I will need to adjust the regulator to 49 lbs.

Any other thoughts on what would cause a very rough idle ever time it starts up cold? The only other issue I am having as far as performance is a 'flat' spot in acceleration around 2800 rpms then above that it seems fine.

Does anyone know how to shim the regulators to adjust fuel pressure? I have heard you can do this easily as opposed to buying an adjustable regulator.

I am using the '96 fuel pump which has a built-in regulator on the pump but my fuel rail also has a regulator on it so it is not original with this '96 motor. Right now the return line is plugged as you don't run one with the '96 systems.

I am thinking of going with a Ford truck external pump to get the 49 lbs of pressure needed and I will need to adjust the regulator to 49 lbs.

Any other thoughts on what would cause a very rough idle ever time it starts up cold? The only other issue I am having as far as performance is a 'flat' spot in acceleration around 2800 rpms then above that it seems fine.

I am dyslexic but I am also cross-eyed so I can read perfectly well.

- 4.whoa

- Movin on up ^

- Posts: 329

- Joined: March 2nd, 2010, 5:50 am

- Vehicle Make: jeep

- Vehicle Model: xj&mj

- Location: Grandville,Mi

Re: 4.0 head and EFI on a 4.2 block

Are you having a fuel pressure drop @2800? Before you crank it up, let the fuel pump prime or pump up for a few seconds and see if that fixes the rough idle.

My xj sometimes has a rough idle @ start up.It's losing a little water,and i think thats why.if i bleed the water press off when i park it, it usually doesn't do it.

My xj sometimes has a rough idle @ start up.It's losing a little water,and i think thats why.if i bleed the water press off when i park it, it usually doesn't do it.

-Russ

4wd is fun, but 2wd is a BLAST

4wd is fun, but 2wd is a BLAST

-

92tank

- I made it to triple digits!

- Posts: 188

- Joined: August 21st, 2010, 6:32 pm

- Stroker Displacement: 4.5

- Vehicle Year: 1992

- Vehicle Make: Jeep

- Vehicle Model: Cherokee

Re: 4.0 head and EFI on a 4.2 block

my jeep run rough on start up with the stock injectors, then cleared up. but after i put the new ones in that issue went away. just food for thought

Who is online

Users browsing this forum: No registered users and 1 guest