Page 1 of 2

basic porting advice needed

Posted: April 4th, 2009, 6:44 am

by Exos

I am ready to begin my basic port job. I aligned my intake/exhaust gasket yesterday, and I have a question : The holes in the gasket for the exhaust ports are much bigger than the exhaust port entries. If I follow instructions from Standard Abrasives and match the port entries with the gasket, I will be removing lots of metal. I am not sure about this. Any advices? What did you guys remove?

Re: basic porting advice needed

Posted: April 4th, 2009, 7:43 am

by Exos

I've read some more. I guess I should leave the exhaust port openings alone, sizewise? How about the intakes? Should they be port-matched with the gasket and intake runners?

Re: basic porting advice needed

Posted: April 4th, 2009, 7:52 am

by Exos

It's amazing how I ask questions and answer them myself...

I've done some re-reading and I get it now. I will port match the intakes but not the exhausts.

Re: basic porting advice needed

Posted: April 4th, 2009, 8:53 pm

by 1bolt

Hold up... Don't "gasket match" anything, this is an old outdated concept that can create a pocket that worsens flow by slowing down the air and making turbulent eddies. Here's an exaggerated illustration:

Gasket matching was the in thing back when casting technology was so bad that the gasket was often more consistent and accurate then either the manifold or the ports. It was a way to "average" out the casting inaccuracies and make all the ports get as close to being aligned with all the manifold runners as possible...

In our case with the 4.0 and derivatives, the gaskets are usually MUCH larger than the ports by as much as an 8th inch around the exhausts and 16th of an inch all the way around the intake ports. Most of them are closer, but I have some gaskets that are just awful and I assume they are factory parts.

What you want to do is match the PORT to the RUNNER if the gasket is really damn close, use it as a guide, but don't create a wider pocket for air to slow down in, you want the runner to be as close as possible to being identical to the port where they meet. Most likely your runners and ports are very well aligned. Most of the intakes/exhaust and heads I've compared where so close to matching that working on them to try and make them better stood a real chance of just making them worse.

Hopefully you also read the Head porting sticky at the top of the forum, lots of good wisdom there.

Re: basic porting advice needed

Posted: April 4th, 2009, 11:25 pm

by gradon

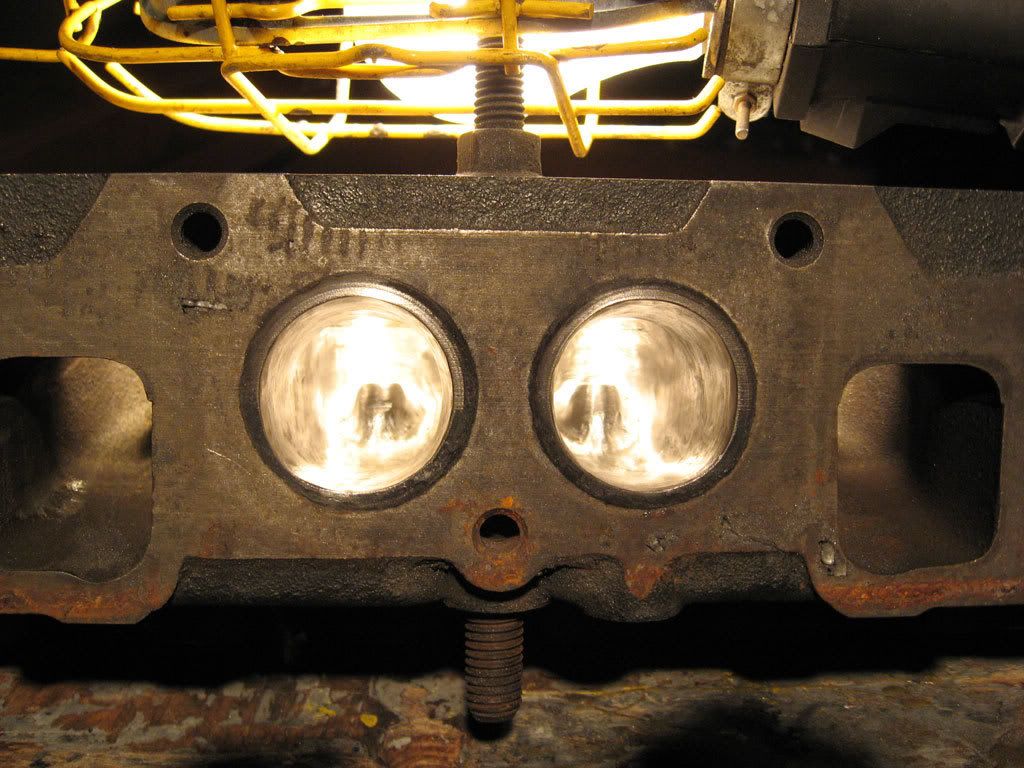

Here's what I did with my exhaust ports:

The black ring around the ports is the carbon build-up from being in the 4.0 with the Borla header--made for a good guideline on what could be removed(still a little step to help w/ reversion).

Re: basic porting advice needed

Posted: April 5th, 2009, 12:05 am

by PolloLoco

1bolt wrote:Hopefully you also read the Head porting sticky at the top of the forum, lots of good wisdom there.

I'm not seeing this thread, do you have a link?

Re: basic porting advice needed

Posted: April 5th, 2009, 8:37 am

by Muad'Dib

Its the only sticky in this forum "Stroker & Performance tech"

viewtopic.php?f=5&t=226

Re: basic porting advice needed

Posted: April 5th, 2009, 9:03 am

by PolloLoco

Now I'm tracking, I was looking for something along the lines of "how to" or "DIY."

I've glanced that thread over, maybe I'll look at it some more.

Re: basic porting advice needed

Posted: April 5th, 2009, 9:04 am

by Exos

1bolt wrote:

What you want to do is match the PORT to the RUNNER if the gasket is really damn close, use it as a guide, but don't create a wider pocket for air to slow down in, you want the runner to be as close as possible to being identical to the port where they meet.

1bolt, if not using gasket as a guide, how else can it be done?

Re: basic porting advice needed

Posted: April 5th, 2009, 11:47 am

by 1bolt

Exos wrote:1bolt, if not using gasket as a guide, how else can it be done?

The question is does it need to be done in the first place? HO Jeep heads and manifolds are pretty good castings from the factory in my experience (except the bowl areas on 7120 and 0630 heads).

You can easily make an exact template of the ports with some paper and then overlay that on the manifolds. mark the bolt holes and alignment dowels accurately.

Just look at the carbon tracking on those pictures above, if you hog out the ports that much you will lose significant low end torque from shortening the effective length of the port. and probably kill horsepower as well due to choking the port with flow reversals.

Re: basic porting advice needed

Posted: April 5th, 2009, 3:42 pm

by Exos

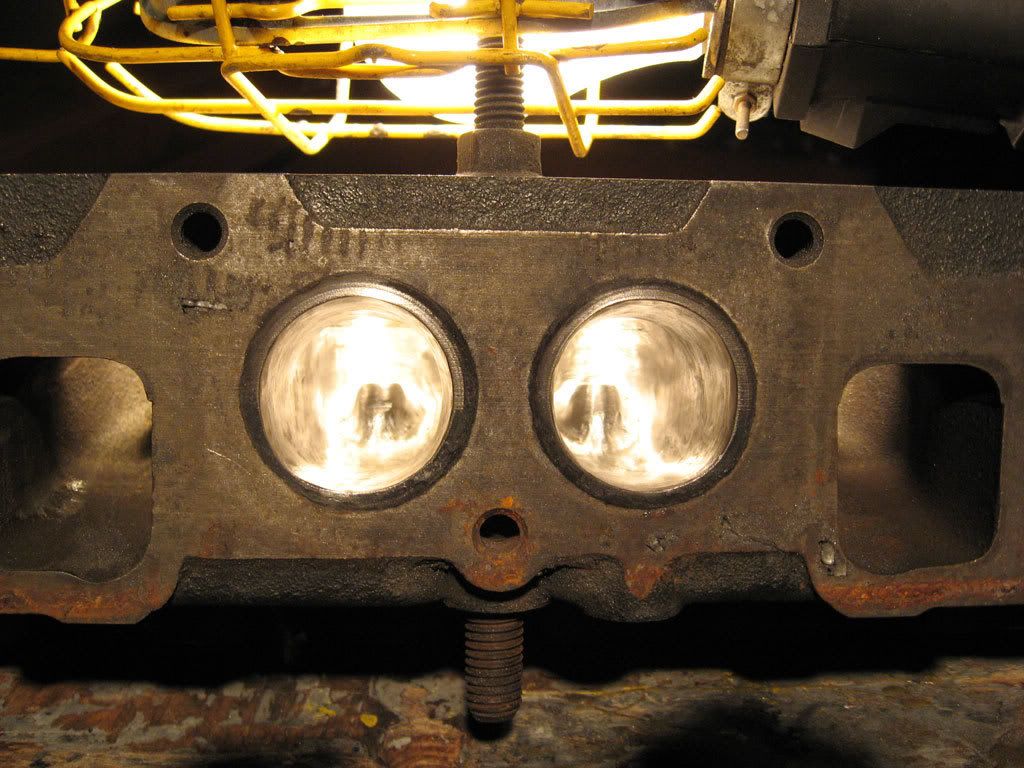

I began my porting this afternoon and I took some pics. I did choose to use the gasket as a guide. First 2 pics are NDT testing (magnaflux) and no cracks were found :

Next pics is gasket in place and lines scribed into paint. I scribed the exhaust anyway, but did not enlarge the entries. I did enlarge very so little the intakes to match the gasket where needed (lower corners) and also ground the gasket a little in some places because it was smaller than opening :

And the last one is the first pass with 40 grit rolls up to just before the bowl.:

I tried the gasket on the intake manifold. If I want to match the openings with the port entries, I will have to enlarge the runners ends about 1/8" all around. I would have to do that even if I did not touch the intake ports. The amount I removed from them is next to nothing anyway. So should I enlarge the runners entries to match them with the intake ports?

Re: basic porting advice needed

Posted: April 5th, 2009, 7:36 pm

by gremlinsteve

do not touch to floor of the ports. leave them alone. polish them out is all you want to do.

match up the intake is fine, i would leave the xhaust alone. just polish the port.

have the machine shop put a good valve job on the head. when they cut a good 5 angle job, they should be able to drop that cutter into the bowl some for you and open that up. thats where you will see most of your gains.

good luck

steve

Re: basic porting advice needed

Posted: April 7th, 2009, 5:57 pm

by Exos

From another thread :

SilverXJ wrote:You should see where the valve sealed against the seat, that is the important part. If you are grinding the combustion chamber drop two old valves in to protect the seats.

Mgardiner1 wrote:Yes, valve seats are generally replaceable.

They aren't replaceable stock, but they can be cut out and a new seat installed. However, one person tried to replace them with diesel seats and cut into the water jacket, making his head scrap.

I was grinding the ridge just below the valve seat, in the throat. My concern is that I might not be able to have a 3 angle valve job done if I go too close to the seat. The 45 degree cut where the stock valve seals was untouched.

I'll try to think of taking a picture tomorrow, and maybe someone could tell me if the valve seat is toast.

Re: basic porting advice needed

Posted: April 8th, 2009, 2:51 pm

by Exos

Re: basic porting advice needed

Posted: April 9th, 2009, 2:52 pm

by Exos

Any opinions? I personally think that it will be ok...?