Edelbrock Head Ported

Posted: May 29th, 2015, 5:06 pm

Just finished working over Edelbrocks new 4.0 Jeep cylinder head.

The purpose of this thread is to help evaluate the head in it's stock form as it comes from Edelbrock, and how well it

responds to larger valves and port work.

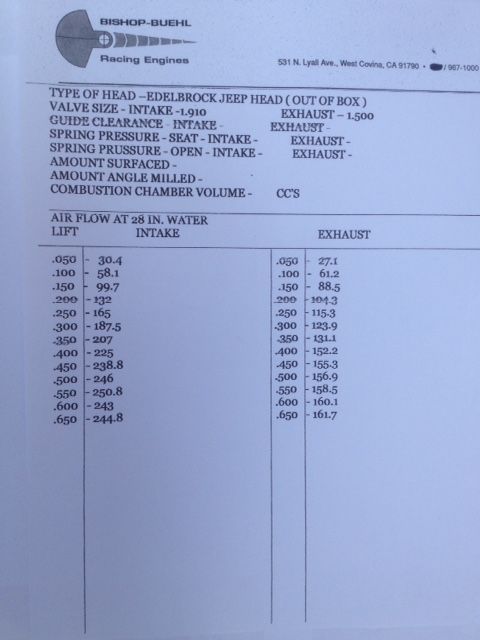

Edelbrocks assembled version comes with OEM diameter valves measuring 1.910 for the intake, and 1.500 exhaust.

The 7120 heads I do is usually loaded up Chevy LS valves measuring 2.000 and 1.550.

The Edelbrock comes with a 1.600 OD seat, so no problem running a 1.550 exhaust valve but because their infinite wisdom

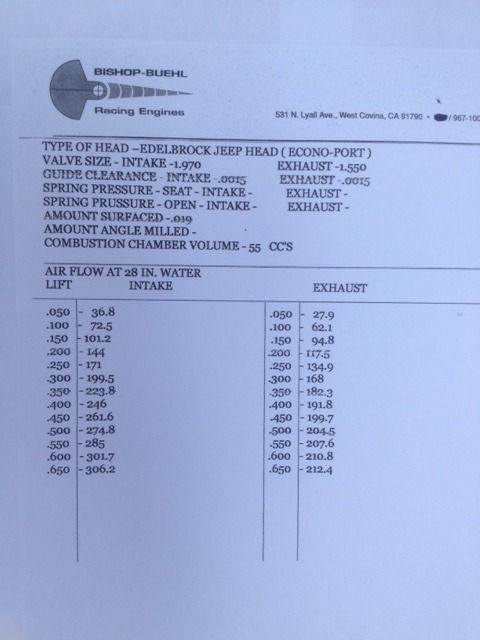

(sarcasm) of putting in a 2.000 OD seat for the intake I reluctantly had to cut my 2.000 Manley valves down to 1.970

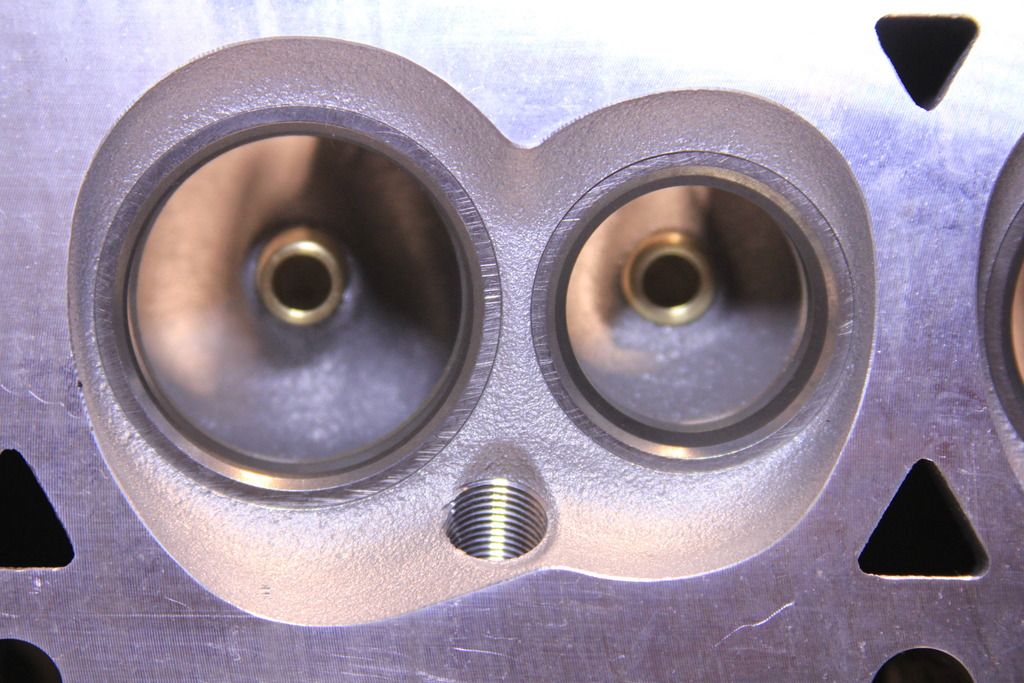

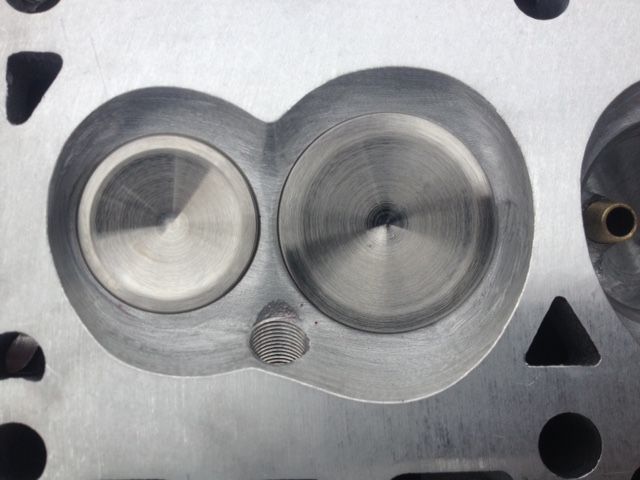

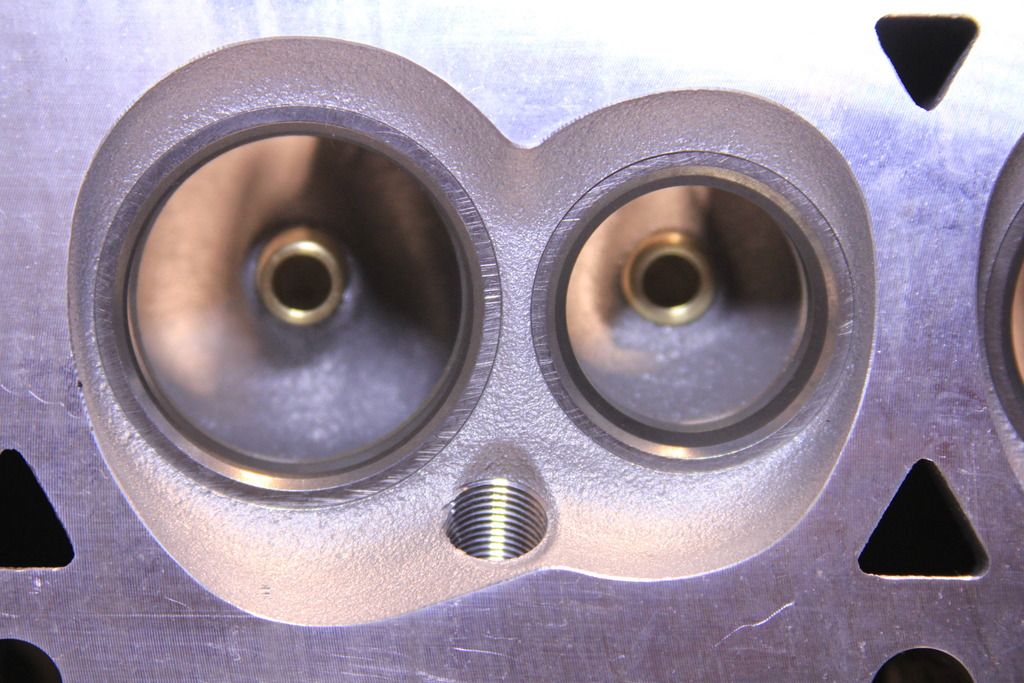

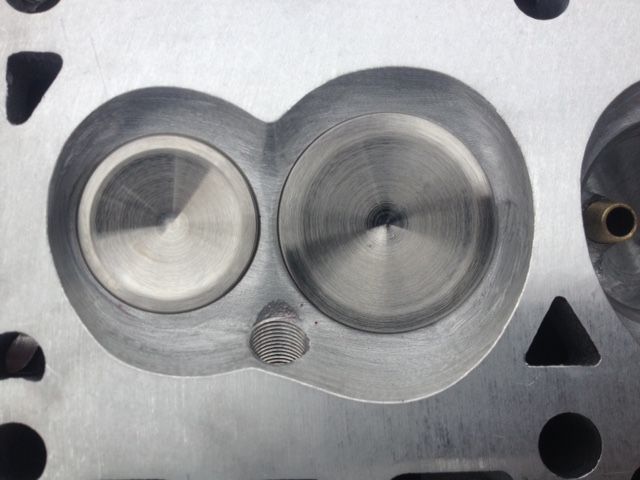

The one major significant change that Edelbrock made was in their combustion chamber and was one of two areas

that really responded to the reworking.

When installing larger valves in a cylinder head its critical to pay close attention to the areas of the chamber walls

surrounding the valve opening. As the valve diameters increase, the edge of the valve gets closer to the chamber wall. To fully receive benefits from running a larger valve one has to address the problem of getting air/fuel past the valve and not allowing it to be chocked off by the chamber wall.

The other area that helped airflow was addressing the restrictive head bolt casing at the entry of the intake port.

Laying back the area of the casing and straightening up the runners gives the air fuel mixture a straighter shot to and from the valves.

So now it comes down to the Report card/Flow sheet.

Let me start with a few words about flow benches and engine dyno's. It's a tool much like anything you have in your toolbox or garage. Flow numbers aren't the final answer or judge just as HP and TQ numbers coming off a dyno sheet don't answer all your questions on how good your engine is. They are both tools that help to analyze, diagnose, and compare. As a example my flow numbers are approximately 5% greater on my flow bench than Edelbrocks. Much the same for Engine dynos. They can be real close but not exact from one to another. The key point is that if properly operated any flow bench or dyno can be very accurate and consistent.

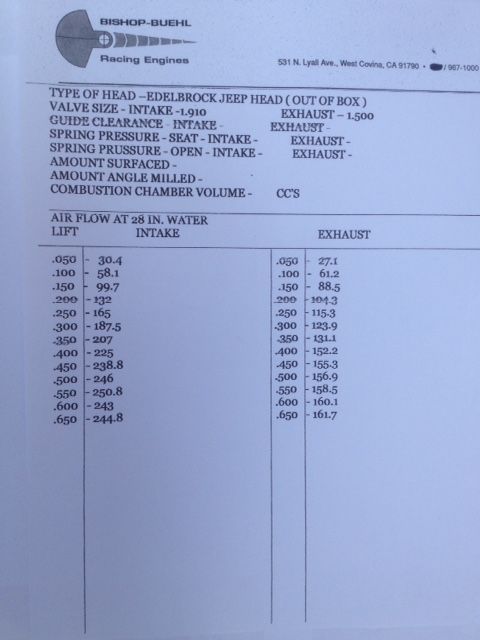

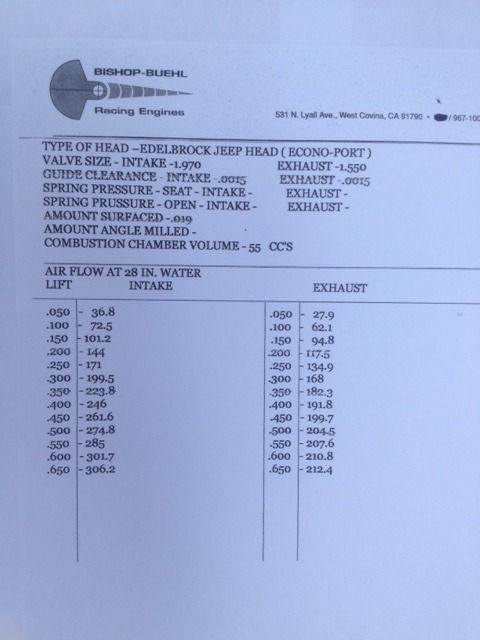

My Flow sheet on the stock out of the box Edelbrock head.

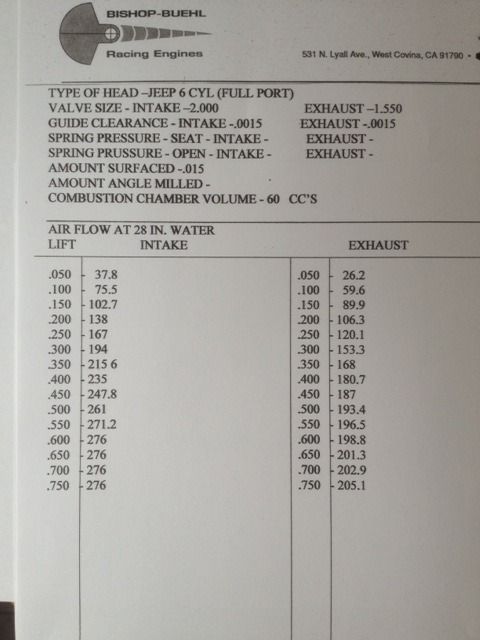

Edelbrock head ported

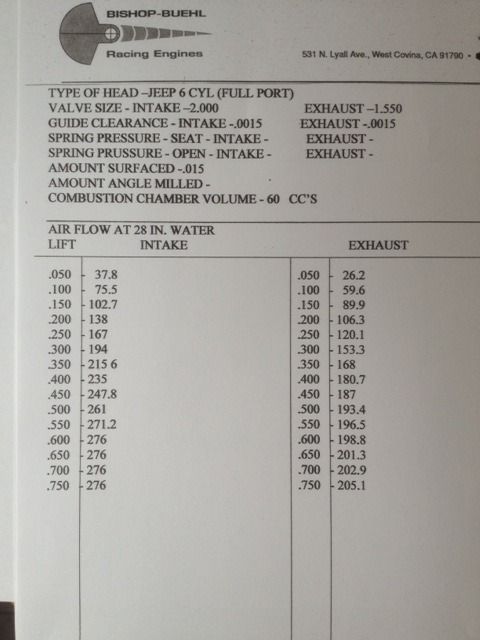

My best flowing 7120 head

The purpose of this thread is to help evaluate the head in it's stock form as it comes from Edelbrock, and how well it

responds to larger valves and port work.

Edelbrocks assembled version comes with OEM diameter valves measuring 1.910 for the intake, and 1.500 exhaust.

The 7120 heads I do is usually loaded up Chevy LS valves measuring 2.000 and 1.550.

The Edelbrock comes with a 1.600 OD seat, so no problem running a 1.550 exhaust valve but because their infinite wisdom

(sarcasm) of putting in a 2.000 OD seat for the intake I reluctantly had to cut my 2.000 Manley valves down to 1.970

The one major significant change that Edelbrock made was in their combustion chamber and was one of two areas

that really responded to the reworking.

When installing larger valves in a cylinder head its critical to pay close attention to the areas of the chamber walls

surrounding the valve opening. As the valve diameters increase, the edge of the valve gets closer to the chamber wall. To fully receive benefits from running a larger valve one has to address the problem of getting air/fuel past the valve and not allowing it to be chocked off by the chamber wall.

The other area that helped airflow was addressing the restrictive head bolt casing at the entry of the intake port.

Laying back the area of the casing and straightening up the runners gives the air fuel mixture a straighter shot to and from the valves.

So now it comes down to the Report card/Flow sheet.

Let me start with a few words about flow benches and engine dyno's. It's a tool much like anything you have in your toolbox or garage. Flow numbers aren't the final answer or judge just as HP and TQ numbers coming off a dyno sheet don't answer all your questions on how good your engine is. They are both tools that help to analyze, diagnose, and compare. As a example my flow numbers are approximately 5% greater on my flow bench than Edelbrocks. Much the same for Engine dynos. They can be real close but not exact from one to another. The key point is that if properly operated any flow bench or dyno can be very accurate and consistent.

My Flow sheet on the stock out of the box Edelbrock head.

Edelbrock head ported

My best flowing 7120 head