CobraMarty wrote:If you are not 'pinging' now with the CPS mod, I would leave it in so it will run great, as it does now, when not in boost and then just dial back the timing with the AEM when in boost.

I'm not fond of pulling a lot of timing out with the AEM as it will also be changing the injector firing as well, however it isn't that critical up at higher RPMs. And I am unsure the PCM would be happy with the cam sensor was seen moving different form the CPS.

The washer fluid reservoir low fluid switch is not a on-off switch, or at least mine isn't, it is a resistance change type of switch. You might be able to tap off the low fluid light wire and directly or thru a solenoid to the AEM map switching wire.

The FSM indicates its a switch both in the wiring diagram and the text

When the fluid level in the reservoir falls below the pivoting float on the sensor, the float changes position and closes the internal switch contacts of the sensor.

But the FSM has been wrong before.

That is an elegant and complicated setup. Why not just, when the low fluid light comes on, you are not out of fluid at that time just yet, try and stay out of boost and stop at the nearest gas station (washer fluid $1.99/gal) or use the gallon jug you have/keep in the back of the jeep to refill the washer bottle.

Not complicated at all, if the level indicator is an open/closed switch. I see no reason why they would have used a potentiometer type switch in it instead of just an open closed switch. I could try to stay out of boost when the light comes on, but that is not an elegant solution. This way I won't have to worry much either.

The vacuum actuator actually works surprisingly very well. I thought of using a 12v solenoid way back and decided against it. No need.

I don't doubt it does, but it would give me greater control over boost and can be tied into the second map function and the washer level switch. That is assuming that that feature does change with the map and doesn't stay constant. I'll probably go with the vacuum actuator for now then possibly play with a solenoid later.

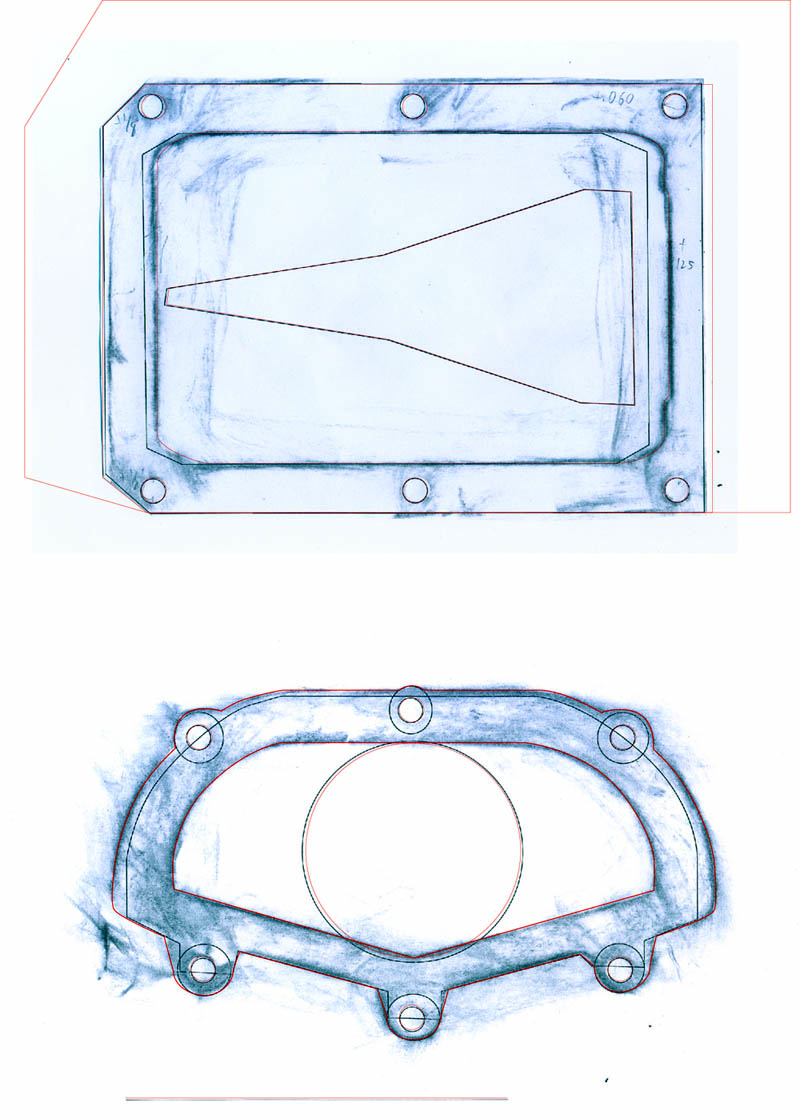

With your manifold angle cut for the flange, Will you have to open up the intake runner walls especially for 3+4 cylinders on the inside of the manifold?

Yes, but I am not concerned with it that that much. It will just resemble the earlier log style manifold and other supercharger log style manifolds for this engine. You can see in the pic where the new top will fall and the runner extensions that will have to be modified. I will probably modify the walls of all of them to reduce their lengths all together to at least try to keep them closer.