93 HO block thermal cleaned, shot peened, 0 decked, bored and honed on Rottler CNC.

4cw Short shout Crank turned 20/20

707 Rods, polished beams, shot peened, and Arp bolts.

Sealed Power 677ACP .030 pistons Dished to 26cc.

Clevite 77 Main and rod bearings

Ported 7120 head with LS1 beehive springs, LS valves/hardware, bronze guide liners, 3 angle Serdi grind. 65cc chambers

Rocker pedestals cut .350 for screw in Comp 4504 studs with Comp 4842 pushrod guideplates

Ford 240/300 ductile rockers 1.6 ratio 3/8 stud.

Lunati 63500 Voodoo cam with a set of Mopar lifters.

Rollmaster double roller timing set.

Hardened 5/16 9.625"ish pushrods.

Mopar Perf/Victor Reniz 54249 .043" MLS head gasket

My Compression (8.6:1)came up a bit lower than I expected

4Cw Crank all prettied up

Side view

677's hangin on the 707 Rods.

Crank and rods all torqued up.

I wasn't planning on the Main girdle, but found one along with the Main bolts at the local pick and pull for 5 bucks

Top view. I didn't take closeups of the notches/bevel in put on the top of the cylinders, but you can kinda see them in this pic. They match up with the chamber walls adjacent to the valves providing a smooth flow transition from the side of the valve to the cylinder wall. I bolted up the head to the bare block and scribed the mismatch then used a carbide burr to correct it. I did this in every cylinder until i could feel a smooth transition between the chamber and the cylinder.

26cc Piston dish...Thanks Oletshot.

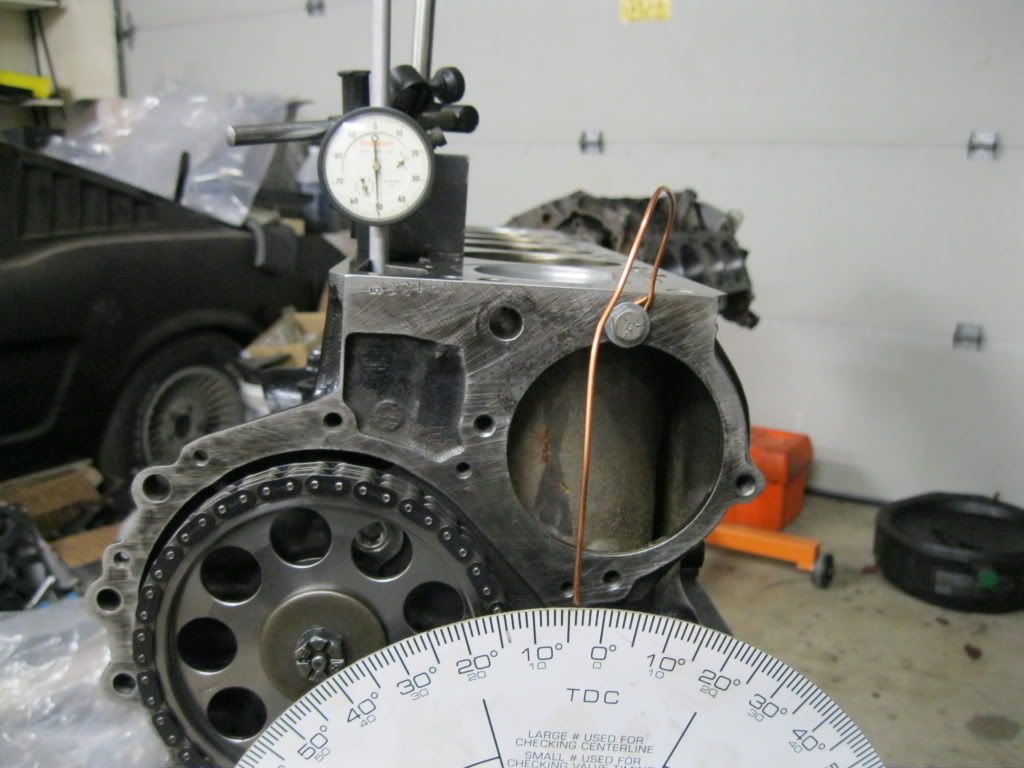

Lunati 63500 installed straight up. Had some issues with the Rollmaster timing set giving me the right phasing. So I had to jockey keyway positions around until I got it at zero....wierd. I also degreed a replacement timing set I had laying around and it had about 12 deg retard. Note to self if you run a aftermarket cam with a stock replacement timing set......

Carbide treatment....

LS valves have a 8mm stem so minimal work is required to adapt.

Intakes were 2.00 I had them cut down to 1.95" and kept the exhausts at the stock 1.55" diameter.

Similarities between 4.0 and LS valves...

Valvetrain hardware going together...

Bottom view shows the extra volume that the LS valves add to the chamber...

Valvetrain geometry check! Dinky spring installed for running a tip pattern. Lucky! Came up really close on the first guess at pushrod length.

Had some 1.75 ratio Crane roller rockers for a GM 250 I-6 they would also work but needed different pushrod length...

I'll stay with 1.6 till The motor is dialed....

Head bolted up, Valvetrain put together! Polylocks set the lash at 1/2 turn past zero lash. The Ford pieces fit nicely.

A fresh coat of black and silver urethane, and it's Goin in! A BBC damper bolt works perfect for this motor and it has an extra tall head to make turning the motor over easier:)

I probably forgot something somewhere... but at least I finally got some pics up! More to come