Page 1 of 10

Gradon's Stroker Project

Posted: March 28th, 2008, 8:56 pm

by gradon

So I am in the process of building a 4.6l stroker for my 96 2dr 2wd ax15 XJ. This is the 4th 2dr 2wd 4.0 5-speed xj I've had(88, 92, 94, and now 96). I love Jeeps(and BMWs) and have been tinkering with them for at least 13 years. My 96 is currently maxed out with bolt-ons: Borla header and cat-back, Magnaflow cat(I just got another one with 2-o2 bungs so I can use a wideband to monitor AFRs), smoothed out 99+intake, 62mm TB, K&N FIPK, Jet 2 chip, Magnecor 8.5kv wires, Addco swaybars, Springworks custom springs(lowered about 1.5"), Bilstien shocks, 255/60/15 Yokohamas, Auburn LSD w/ 3.55s, ZJ rear discs, adjustable map, Hurst shifter, and I'm probably missing a few more mods. Anyhow I've gotten dirty on almost everything on the XJ (axles, trannys, clutches, suspension, etc)except for inside the engine. So after I rolled my 94, which had most of the same mods, I had a good engine to sell or use for my very own stroker project. Naturally my love of the cherokees has rubbed off on my brothers. One of them, Nick(who is stationed in the gulf), was planning to stroke and turbo his XJ. He bought the 12 weight crank, 4.2 rods, and a nice T3(still sitting in the shed). He said I could use whatever and so I immediately traded the 12w crank for a 4w crank(the one with the long nose, but it'll do). I was originally going to use the 4.2 rods and the h802cp pistons(and still might), but have held off to see what KB is going to offer(hopefully a piston with a low 20cc dish and 1.38 pin height). The cam I have is the Mopar 4529230ab(256* dur./ .450" lift /40* overlap). I've ordered the 5249464 springs with the req'd retainers, keepers, seals, and the gasket teardown set(w/ .043" HG) already. I am in the process of porting and polishing the 94 head(tomorrow I'll put at least 3 or so more hours into it--it's gonna take at least 10 total). Anyhow I am shooting for a high compression(9.5-10.1:1SCR, 8.1-8.5:1 DCR) engine that'll use every bit of the 93 octane that is available. I'll start off using a wideband o2 and the adjustable map to tune it and then get a Split Second PSC-1 to really fine tune it. Anyhow my bro has 3 weeks leave in May and I wanted to have it all ready to put together and in when he's here, so I've got a lot of parts to still buy and machine work to be done(which is why I need to hurry up with the p&p and get the head to the machinist). Anyhow, I've been receiving the emails from the yahoo group for over a year, so thanks to all of you for the info, time, this site, etc. I'll keep you posted with updates. . .

Re: Gradon's Stroker Project

Posted: March 28th, 2008, 9:51 pm

by seanyb505

What is the brand and part number for your teardown gasket set? I have a Victor Rienz set and I know they make a .043" gasket, but the guy I ordered from just said it was a replacement gasket.

Re: Gradon's Stroker Project

Posted: March 29th, 2008, 8:11 am

by gradon

I ordered mine from Mopartsracing.com(Jeepconnection.com). The gasket tear down set is # 4529245 and the individual head gasket is 4529242.

Re: Gradon's Stroker Project

Posted: March 29th, 2008, 10:36 am

by seanyb505

Crap! I specifically did not order from them cause they said it came with only a replacement gasket. I wish people would know what they sell.

Re: Gradon's Stroker Project

Posted: April 1st, 2008, 6:23 pm

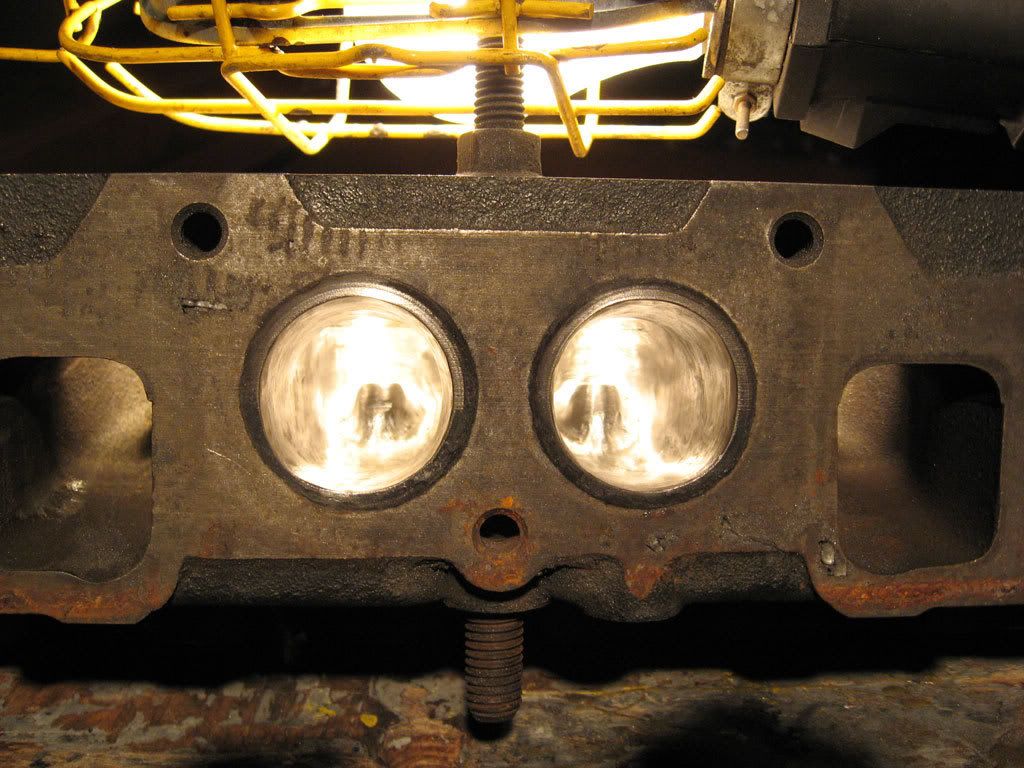

by gradon

Re: Gradon's Stroker Project

Posted: April 2nd, 2008, 6:04 am

by Flash

Looking good,

Flash

Re: Gradon's Stroker Project

Posted: April 10th, 2008, 2:06 pm

by gradon

So I opened up the gasket tear down set and it turns out to be fel-pro, my brother who works at AA said the p/n on the hg: 9076pti is a fel-pro #, so it looks like I got the .051." One of the valve seals is an oval--got smushed a lil somewhere along the way, so it looks like I'll have to make a call to Mopartsracing. I might keep it if I decide to go with the 10:1 KBs so I can keep the comp ratio down. I don't like the multiple piece cork gaskets either. One other question: I ordered the 4452032 chrome-moly retainers. They sent them in a bag(not a box with a p/n) and they are black, not shiny chrome like I thought they would be. Does it sound like they sent me the $2 cheaper P4529216 or 7 regular steel retainers? Anyhow, I'm gonna put a few more hours in on the head tonight so I might be back with some pics.

Re: Gradon's Stroker Project

Posted: April 11th, 2008, 3:52 pm

by gradon

I finished up the head today and took it to the machine shop(Tacho's Torneria in Hyattsville, MD). All in all it took me 12-14 hours to do it. I went there a few years ago to get my flywheel machined. He recognized me--we talked in spanish(I like to use it when I can). I asked him what kind of deal he could do for me and he said $235(no tax) for the cleaning, valve job, machined bare minimum, and he is gonna do a pressure test as well(make sure I didn't port too much). He was impressed with the port&polish job, so that was cool. I also told him that I would be back w/in a month to get the block cleaned, decked .020(for the KBs or .030 for the SPs), bored .020, cam bearings pressed in and rods pressed on pistons($400-500, probably--I'll find out on Wednesday when the head is done).

Re: Gradon's Stroker Project

Posted: April 11th, 2008, 4:02 pm

by FrankZ

Don't forget your 1cm spacer for the crank or have it cut down. I'd also strongly suggest getting the rotating assembly balanced. No sense taking a chance on an out of balance crank.

Re: Gradon's Stroker Project

Posted: April 11th, 2008, 4:25 pm

by gradon

I wasn't sure what I was gonna do with the crank--spacer or cut(will the keyway be enough to hold the 4.0 HB after it's cut?) I will get him to check out the crankshaft, even though the person I traded my 12weight for said that the shop he took it to said it was fine after they chamfered the holes.

Re: Gradon's Stroker Project

Posted: April 11th, 2008, 5:04 pm

by FrankZ

Cutting the snout is fine, lots of folks go that rout. Hesco makes a 1cm spacer but they are very proud of it ($$) I hacked up an old balancer and made my own...I'm a cheap S.O.B.

Re: Gradon's Stroker Project

Posted: April 12th, 2008, 2:57 pm

by gradon

I would go the balancer route, but for some reason CJs don't make it to the JY I regularly go to. I'll take a look next week when I go. I'll put out a wtb ad on Jeepsunlimited, and see if anyone has an old one laying around anywhere.

Re: Gradon's Stroker Project

Posted: April 12th, 2008, 4:16 pm

by FrankZ

A balancer from any 258 will work for a homebrew spacer. Waggy, CJ, YJ, J-Truck.

Re: Gradon's Stroker Project

Posted: April 24th, 2008, 2:16 pm

by gradon

Re: Gradon's Stroker Project

Posted: April 24th, 2008, 3:10 pm

by aaronkeiser

Is it possible to run the ones that came off the head in the first place. Then after you get the motor running right you could make the switch so it hurts less on the bank account. All they guys on hear say they are a sinch to install.