Bit of an update.

I learned that there was an after market thrust plate style cam available so I looked into getting one custom ground for my stroker. The stock grind is sold by Melling, but Melling doesn't grind their own cams so I figured that the blank has to be available. I was a bit concerned that that solid pin would eventually wear the cover out and teh cam would start walking, which would eventually eat the bearings and put me back at square one. Besides the advantage of the thrust plate style it also has the wide lobes. I talked to Crane, Comp, Isky and Jones Cams. Crane, Comp and Isky said they couldn't get the blank and wouldn't even bother checking for me. Its a shame because i really liked that Isky grind I had despite their horrible service. Jones Cams came highly recommended by the people on speedtalk.com (besides Naxja and here I spend a great deal of time reading there). After a few calls back and forth with his blank supplier he was able to locate a cam blank. I went something with a bit less over lap than the Hesco because I wasn't happy with the idle quality. It was a bit rough and sounded like it has a lean miss in the exhaust at idle. I liked the higher RPM performance of the cam though. I know Hesco puts these in the majority of the strokes they produce so I don't know quite why it wouldn't play well with my combo. Maybe because my stroker is "special", and when I say special I mean as in the special olympics special. I went with a 260*/204* duration, .472" lift on the intake and 264*/208* duration with .478" on the exhaust. LCA 113*, 109* intake center line.

When I removed the Hesco cam the cam bearings looked fine with no wear. I used a stock style silent link timing set. Initially the cam end play was at .007", but I wanted it tighter. After a bunch of figure 8s on sand paper with the gear I landed on .004", which is what I wanted. The only hitch with the install was that when I went to degree it the cam was 5* retarded. I fixed this by using a 4* crank woodruff key for a SBC (Mr. Gasket 988G). It needed some massaging to get it to fit 100%. Jones Cam's said that in order to grind advance into it he would need to reduce the base circle by .015" for every degree. That didn't sound like a good idea. So, it appears that the blank doe shave some draw backs. As is the cam 1* retarded, which I would doubt I will notice.

I ran the break in without issue and ran it 300 miles on the Joe Gibbs oil as recommended. I checked my cam bearings once again today and they are still fine! Timing set looks good, cam end play is where i set is as well is crank end play.

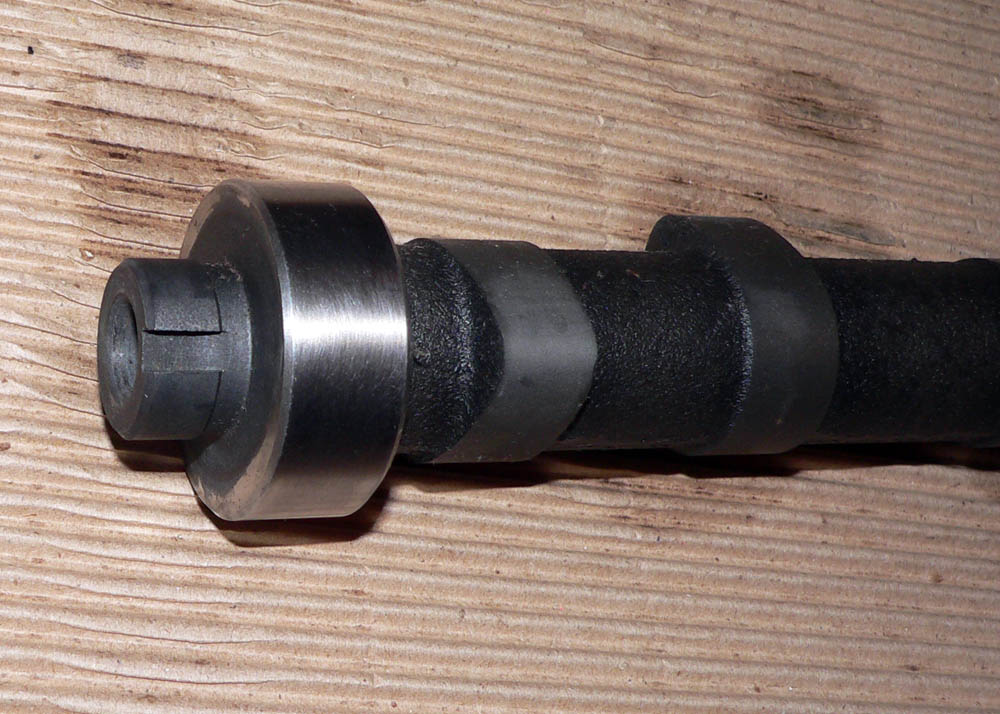

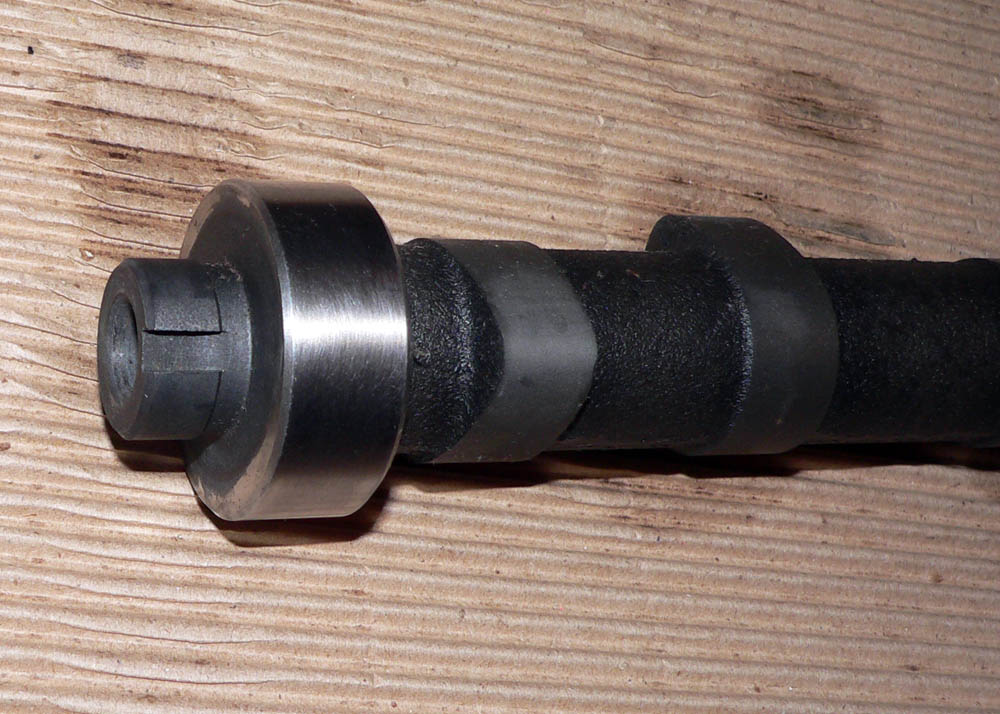

Wide lobes, and later cam snout.

I am learning to weld so I made a cam removal and installation tool. One end is threaded for the old style cam, one for the new style cam. I should have made it longer for in vehicle install. Afterwards I had a co worker powder coat it for me then threw a JeepStrokers decal on it.

Cam installed and thrust plate bolted on. Note the oil holes to lube the cam gear.

.004" cam end play:

I also picked up an ARP bolt for the harmonic balancer. It has both a hex style head and a spot for a 1/2" ratchet. It has the same threads as the stock bolt, but it was a little long so I cut it down on the lathe. Turning the crank over is so much nicer now as I don't have to worry about the socket falling off the bolt. Plus it compliments the ATI balancer well.

The engine has ~5000 miles now since the last cam bearing failure.