Page 3 of 9

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: February 27th, 2009, 7:23 am

by Plechtan

I was working on the Timing belt drive as well, but allot of issues. I did come across some other information tha will help with a low cost gear setup. The cam to crank spacing on the jeep is the same as the ford Fe, 351C Olds 455. Chevy 348-409, and a few others.

Milodon makes a 3 gear setup. Part numbers are 14500 for the Fe, 14200 cor the 351C 1400 for the olds. These would require a plate to hold the ideler gear. You coud probably use the template for the timing chain cover to make a 1/8" plate and just space the cover foward a little, you might need a spacer on the damper. Another wau to go would be to make a block that bolted to the bottom edge of the block right next to the main cap to hold the idler gear.

Edelebrock makes a setup similar to the old Chrysler 4 gear setup Part number 7896 for the 351C .

In both cases you dould have to do some work on the crank and cam attachment points. The milidon uses a bolted hub on the Cam, so it would be easy to make a new one. you may have to make a sleeve for the crank to get it big enough. The edeleborck does not have a hub on the cam and would require machining.

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: February 27th, 2009, 9:16 am

by John

I am still doing some checking but I think the Olds rocket 350 is the same dimension and timing gear sets are available for them as well.

John

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: February 27th, 2009, 2:22 pm

by SIXPAK

My belt drive should be done within a month or so. Just bought a BBC unit and adapting it over. BTW, Jesel is coming out with a Ford FE unit that uses the BBC pulley/belt combo. Danny Bee makes one for the Ford FE also but I chose to go with CV products set up with the roller cam hub.

BTW John, AFIAK there is nobody baking a belt drive for the Olds Rocket, I called BOP Engineering.

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: February 27th, 2009, 4:09 pm

by John

Sixpak, I was actually thinking of a old howler timing gear set. Like this

http://store.summitracing.com/partdetai ... toview=sku.

John

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: February 27th, 2009, 7:31 pm

by amcinstaller

depending on the crank that you use, you may not need any spacers of any kind. on some cranks, the nose is about 10mm longer, that should be sufficient length to house these id think. but then again, im no engineer.

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: February 28th, 2009, 12:25 am

by TurboTom

A gear drive is the LAST thing I will put on my engine.. I want to make HP not noise.

As long as you realise you need an Idler pulley on the belt drive, the pulley choice gets easy.

Ain't nothin a mill and a lathe can't fix

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: March 1st, 2009, 8:05 pm

by SIXPAK

True Dat!

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: March 1st, 2009, 9:25 pm

by TurboTom

Got to work on some engine stuff this week

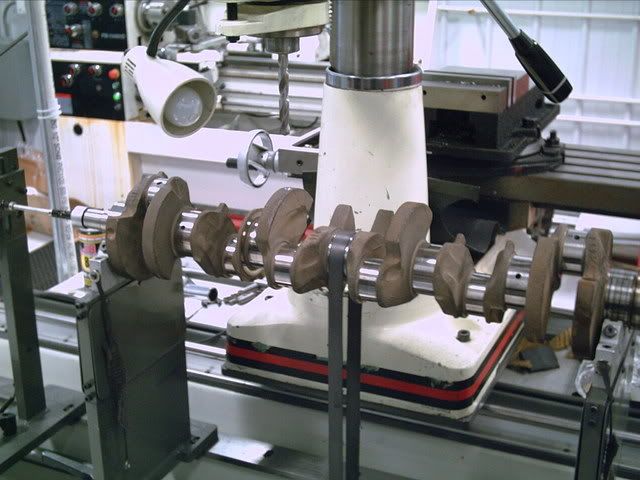

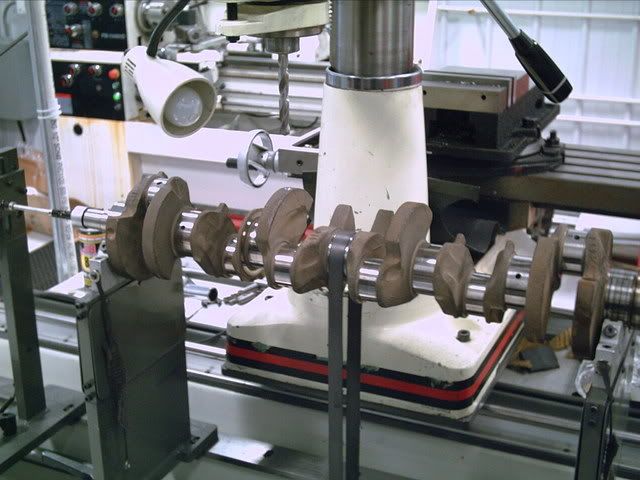

First we balanced the crank. I must say everyone was impressed with the factory balance job.

Less than 3 grams @ 3". With very little work we got it down to Less than 1gram @ 1"

My friend Steve is always up for a Photo Op ;D

Started porting on the head, Not looking to strike water, just clening up the worst stuff. Of course I still have to do the valve job and blend everything in.

Stock Port

Better Port

I am waiting on a Torque plate and then I will fit the new pistons

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: March 2nd, 2009, 4:26 am

by SilverXJ

Where are you getting tthe torque plate from?

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: March 2nd, 2009, 8:01 am

by TurboTom

SilverXJ wrote:Where are you getting tthe torque plate from?

It was made by BHJ part# AM-6.

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: March 2nd, 2009, 9:25 am

by SilverXJ

Wish I had known that was available. I asked Hesco about one and they no longer sell them and have one for their use only.

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: March 2nd, 2009, 9:59 am

by dwg86

Does using a torque plate make that much of a difference on a steet engine? I know they are good to use if available. I have built many engines, but most of them being odd ball engines(amc 304,401 Ford 352,360 amc 196, Olds 389,455) and most machine shops don't have torque plates for them, so I have no referance on what to expect or how much a block gets distorted when a head is bolted on.

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: March 2nd, 2009, 6:33 pm

by TurboTom

dwg86 wrote:Does using a torque plate make that much of a difference on a steet engine? I know they are good to use if available. I have built many engines, but most of them being odd ball engines(amc 304,401 Ford 352,360 amc 196, Olds 389,455) and most machine shops don't have torque plates for them, so I have no referance on what to expect or how much a block gets distorted when a head is bolted on.

Some engines I have worked on move around alot with a torque plate. I have seen them pinch the bore as much as .002" across head bolts.

I will measure the bore before and after the plate, to see how much the 4.0 is affected.

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: March 6th, 2009, 5:21 pm

by SilverXJ

TurboTom wrote:

I will measure the bore before and after the plate, to see how much the 4.0 is affected.

That would be good info to know.

Re: Flogging the wee wee out of a Jeep 4.0 I6

Posted: March 6th, 2009, 7:28 pm

by 1bolt

It occures to me I should just google this but what exactly goes into making a torque plate, I know it's use and function, what I mean is, does it need to accurately simulate the rigidity of the head itself, or is it just a machined steel plate of arbitrary stiffness with the proper holes for the head bolts and bores to allow the hone through?

I wonder how much of the torque plate's function is simply being something for the bolt head to torque up to and pull upward on the block threads thus distorting the bores... Versus the actual rigidity of the plate itself exerting upward stress on the block deck...

If the rigidity is arbitrary then anyone with a drill press and a 4" hole saw could make a torque plate... We could pass it around from build to build, charging only shipping + a couple bucks (maybe 20 or 30 bucks total) to defray the initial steel cost and labor and have a reasonable loaner tool deposit that would be refunded each time it got returned. $20-$30 versus buying a torque plate for one use, or just going without... I think I'd pay the $20-30.