Re: 4.6 build

Posted: September 8th, 2012, 9:23 am

It's Getting longer and longer.

I'm going to try and put it in in one piece, I don't quite know how that's going to work out.

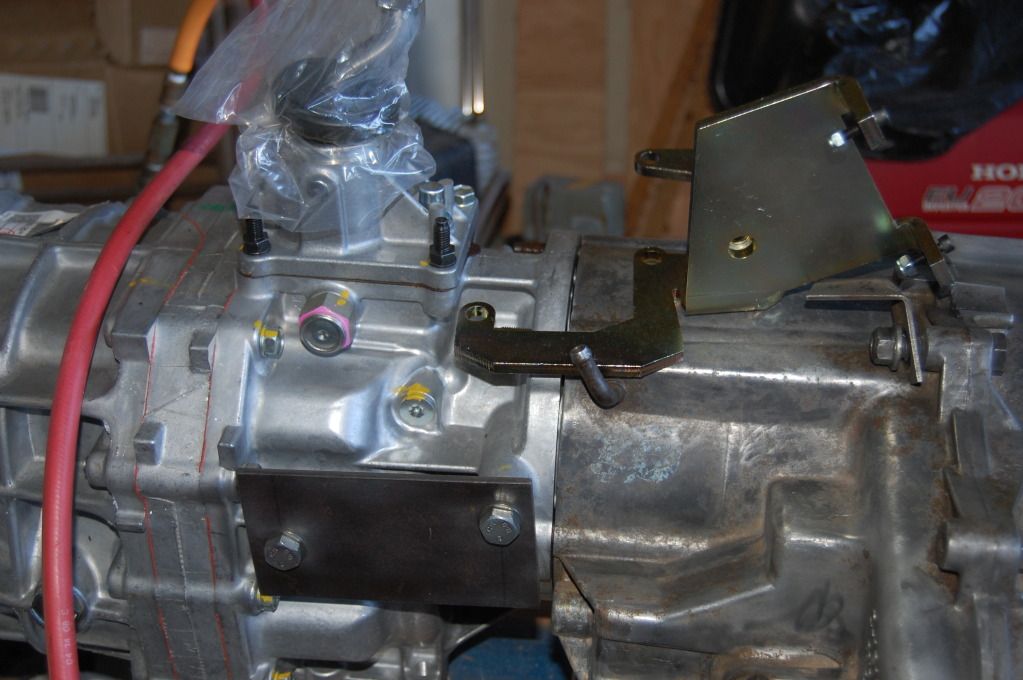

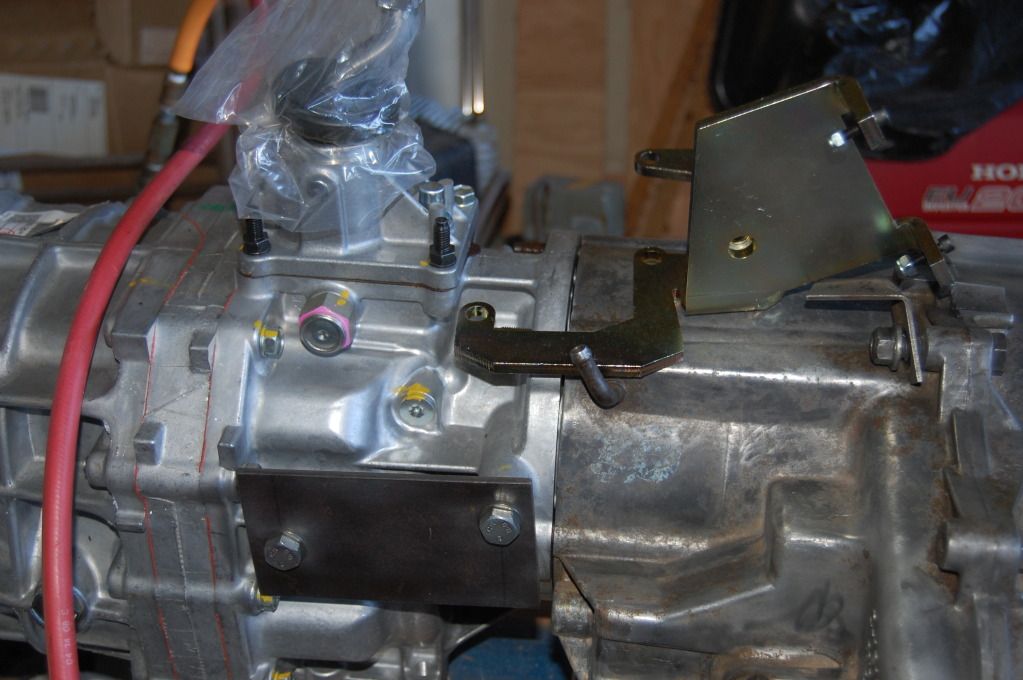

Close up of the 231 with the SYE, had to change the input shaft to match the AX-15.

Notice that the 231 is rotated about 10 degrees clockwise from the orientation when installed with the Ba10/5.

I might have to redrill the transmission, it looks like I have room to rotate and redrill if I have to.

I don't know if the Xfer case will bump up into anything in its present state.

Another problem... The anodized piece is the Xfer case shifter bracket (for an NV3550) .

I think I am going to to fabricate my own shifter mechanism. It goes through a reversing process in the linkage.

So mine will be back to front. I'm thinking about something totally redneck style like a lg box wrench as the shifter handle.

J.B.

I'm going to try and put it in in one piece, I don't quite know how that's going to work out.

Close up of the 231 with the SYE, had to change the input shaft to match the AX-15.

Notice that the 231 is rotated about 10 degrees clockwise from the orientation when installed with the Ba10/5.

I might have to redrill the transmission, it looks like I have room to rotate and redrill if I have to.

I don't know if the Xfer case will bump up into anything in its present state.

Another problem... The anodized piece is the Xfer case shifter bracket (for an NV3550) .

I think I am going to to fabricate my own shifter mechanism. It goes through a reversing process in the linkage.

So mine will be back to front. I'm thinking about something totally redneck style like a lg box wrench as the shifter handle.

J.B.