The evolution of a 2.50" (63.5mm) Throttle Body

Posted: March 20th, 2012, 5:28 pm

So about 5 years ago i started my stroker build (No, i dont have a build thread yet. Yes, Im a slacker) and about 6 months ago i finished the build. Ive driven the Jeep, a '97 Tj on 1 tons and 40" TSLs, everywhere, however, it has lacked some middle/upper end power. Most of this stems from a series of dumb mistakes i make while building the motor.  One thing i desperately wanted to fix, though, was find a way to feed it more cool air. First thing i was route a 2.5" tube into the cowl area where i placed an airfilter.This took my air temps from roughly 170* right behind the rad to a few above ambient.

One thing i desperately wanted to fix, though, was find a way to feed it more cool air. First thing i was route a 2.5" tube into the cowl area where i placed an airfilter.This took my air temps from roughly 170* right behind the rad to a few above ambient.

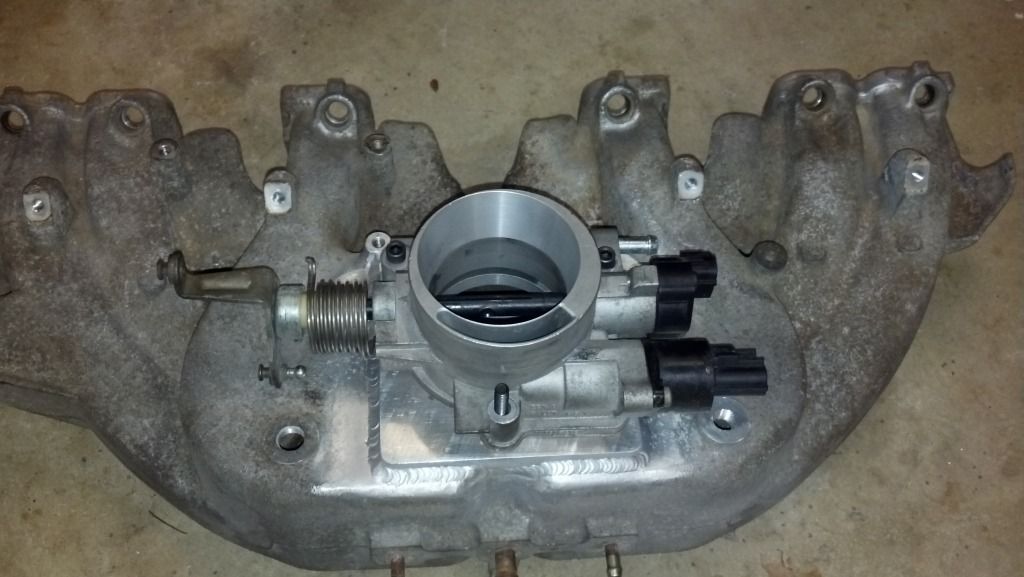

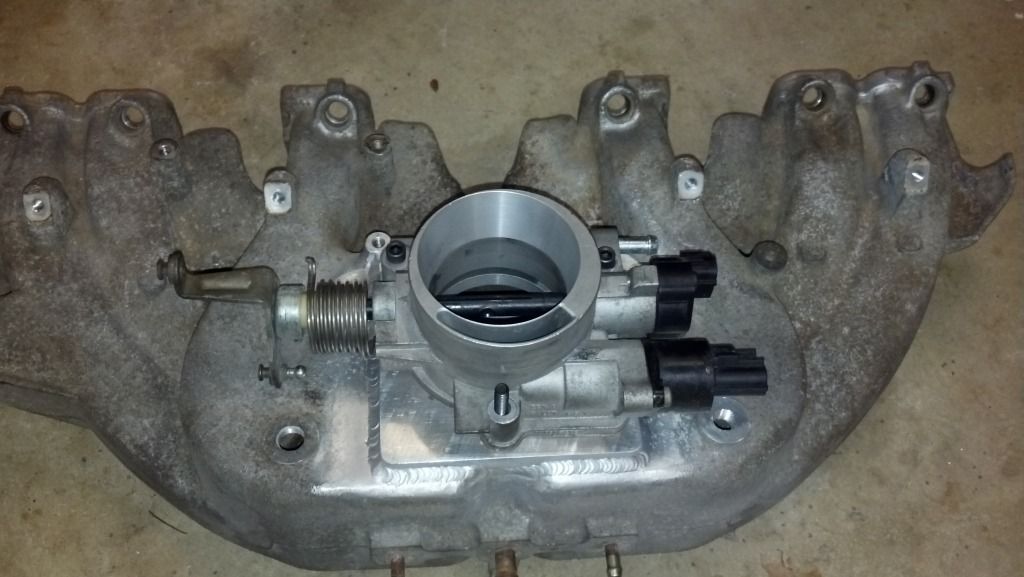

Next, I really want a larger TB but im cheap so i wasnt coming off the $500 for one. Went to the local P&P and gots me another WJ manifold and Durango 63mm TB. Im a machinist by trade so the next few steps where easy. I ported the manifold:

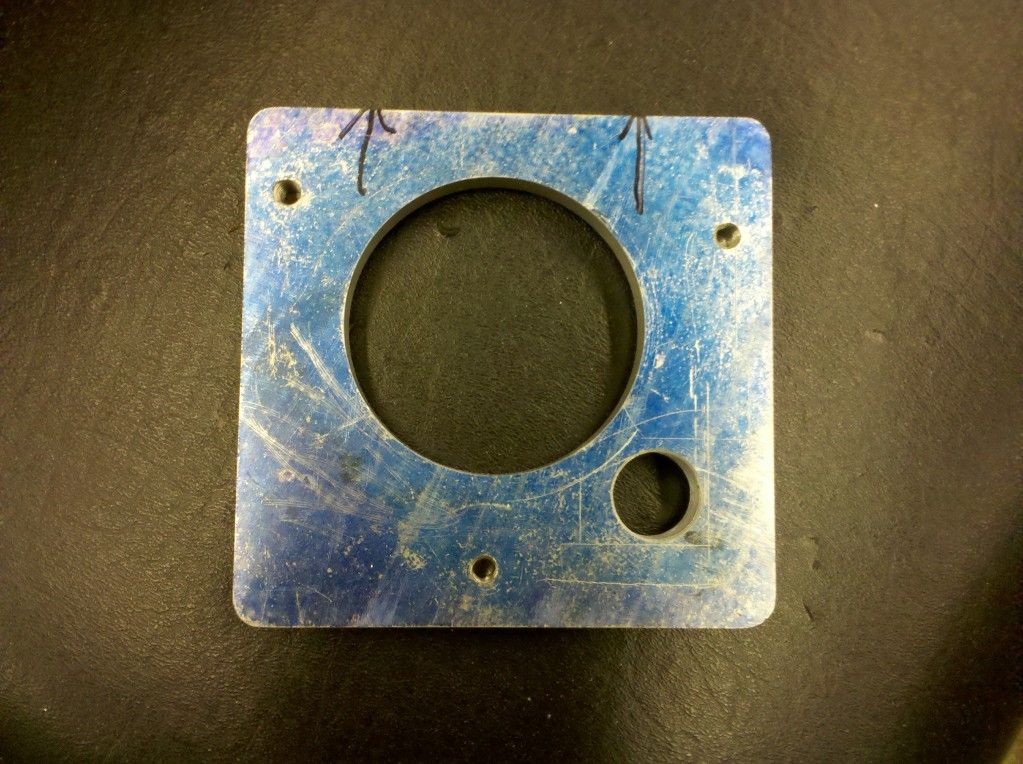

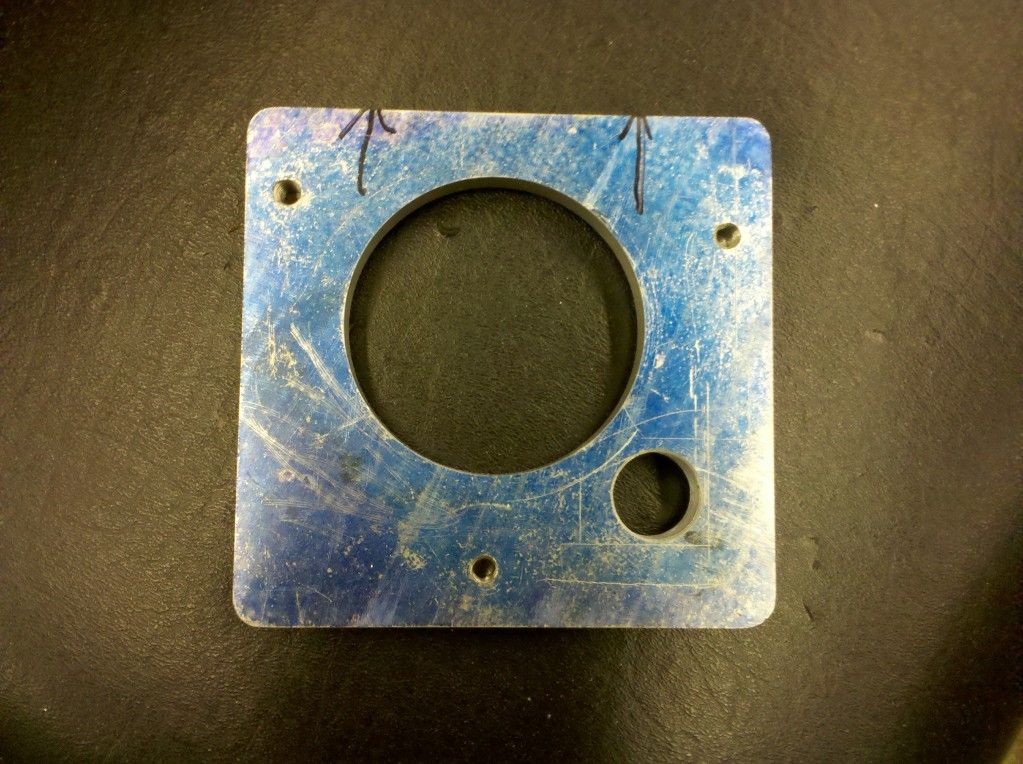

The next step was to adapt the Durango unit to the WJ manifold. I had a few ideas but this one seemed best. I made an adapter plate and milled a pocket in the mani to be welded up.

The idea was to have the centerline of the old throttle blade in the same location as the new one so i could reuse the throttle cable. Long story short: I trashed a bunch of stock TBs to "make" a new TB shaft/pulley and was NOT happy with the results. Back to square one..... One day Ill revisit this idea but for now its under the work bench. I got to looking at an aftermarket TB and realized it looked a heck of a lot like the stocker. A hand full of measurements confirmed that the stocker can be bored out to 6x.xx". The biggest problem was id need a new throttle blade. But hey, How hard could that be!?

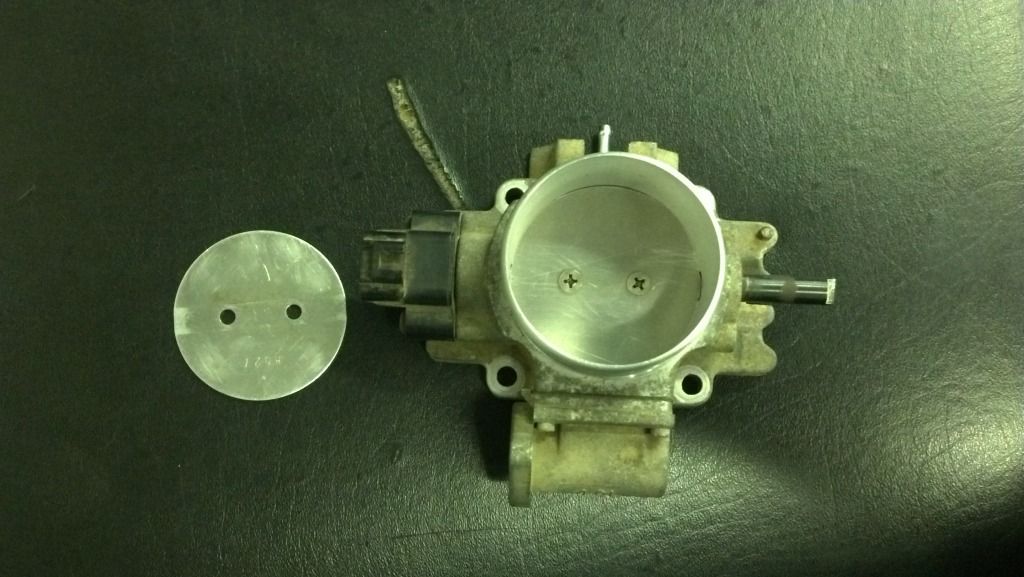

First, i started again with a stock OBDII TB, disassembled it, and flung it in a lathe.

Exhibit A:

Truth be told, i think this could be taken to just under 65mm but its cast aluminium, made by the lowest bidder, so i wasnt taking the chance. The intake tube clamp area gets Uber thin(~.07" IIRC), so 2.500" sounded nice and round to me!

A pic post-turning in my favorite lathe with the stock blade in it:

Ill post up some more pics and info tomorrow. Lemme know what you guys think so far, better yet i love some ideas on the durango TB.

Next, I really want a larger TB but im cheap so i wasnt coming off the $500 for one. Went to the local P&P and gots me another WJ manifold and Durango 63mm TB. Im a machinist by trade so the next few steps where easy. I ported the manifold:

The next step was to adapt the Durango unit to the WJ manifold. I had a few ideas but this one seemed best. I made an adapter plate and milled a pocket in the mani to be welded up.

The idea was to have the centerline of the old throttle blade in the same location as the new one so i could reuse the throttle cable. Long story short: I trashed a bunch of stock TBs to "make" a new TB shaft/pulley and was NOT happy with the results. Back to square one..... One day Ill revisit this idea but for now its under the work bench. I got to looking at an aftermarket TB and realized it looked a heck of a lot like the stocker. A hand full of measurements confirmed that the stocker can be bored out to 6x.xx". The biggest problem was id need a new throttle blade. But hey, How hard could that be!?

First, i started again with a stock OBDII TB, disassembled it, and flung it in a lathe.

Exhibit A:

Truth be told, i think this could be taken to just under 65mm but its cast aluminium, made by the lowest bidder, so i wasnt taking the chance. The intake tube clamp area gets Uber thin(~.07" IIRC), so 2.500" sounded nice and round to me!

A pic post-turning in my favorite lathe with the stock blade in it:

Ill post up some more pics and info tomorrow. Lemme know what you guys think so far, better yet i love some ideas on the durango TB.