Page 1 of 1

Golen install question

Posted: July 7th, 2012, 4:56 pm

by bulfo4

Going from a 1996 4.0L HO to a 4.6L Golen stroker.

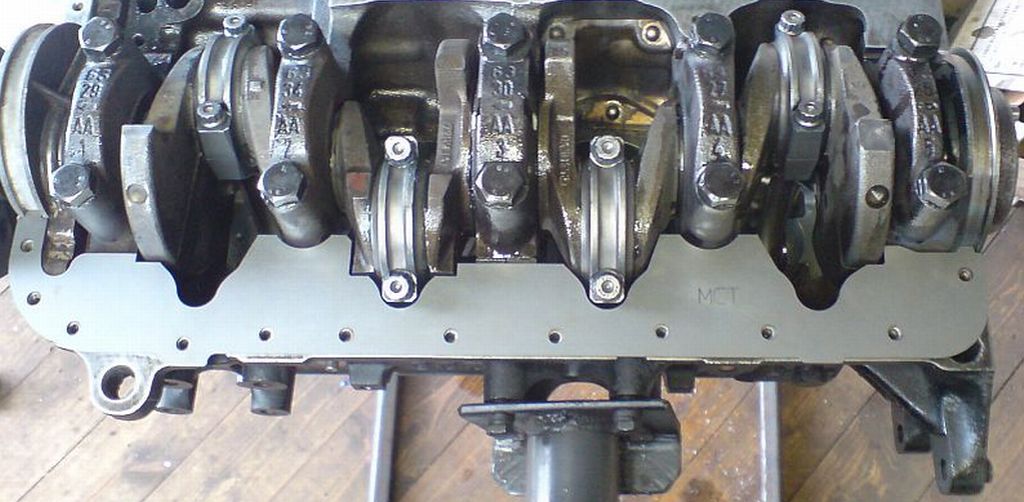

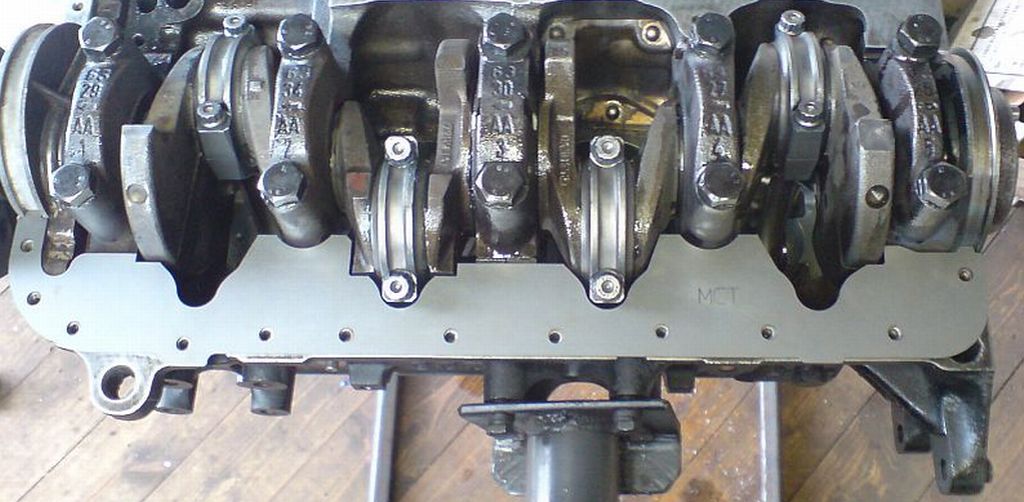

There's a main bearing girdle in the 1996 engine that mounts with studs, then the girlde, then nuts.

The Golen came with big bolts on there that are flat and has no provisions for this brace (also know as a main bearing cap brace).

Do we need to take off the Golen bolts and add on this brace or should we put it together without the brace.

We've been looking everywhere for answers on it and the only thing we've found is that this brace was added to 1996 and later to strengthen the main bearings. If we put this in will the downstoke hit it or will it be clear.

Thanks,

Tom

Re: Golen install question

Posted: July 7th, 2012, 5:29 pm

by cruiser54

It wasn't to strenghen the main bearings. It was to help reduce NVH from the engine. Noise, Vibration, Harshness.

Re: Golen install question

Posted: July 7th, 2012, 6:03 pm

by SilverXJ

I say install it. But you will need to space it about 1/8" to clear the crank. Use hardened washers of the correct size. I had to use two on each "stud"

Re: Golen install question

Posted: July 8th, 2012, 6:32 am

by Retlaw01XJ

bulfo4 wrote:

The Golen came with big bolts on there that are flat and has no provisions for this brace

Do we need to take off the Golen bolts and add on this brace or should we put it together without the brace.

You'll need to replace the bolts with studs to use the brace. Add the spacer washers on top of the studs, just under the brace.

The lowered brace will likely cause the oil pan to not fully seat, so the pan will need to be massaged a little.

Re: Golen install question

Posted: July 8th, 2012, 10:33 am

by bulfo4

Awesome. You guys rock.

So, a couple of 1/8 hardened washers perstud (just above the brace itsenf). Sounds like a plan!

You guys are life savers.

Re: Golen install question

Posted: July 8th, 2012, 11:27 am

by Muad'Dib

I dunno... i just dont feel like its worth it. It doesnt add strength.. it only reduces NVH. Im not sold on the work to implement it i guess. Although i know most guys on here added the girdle. Just my opinion of course.

Re: Golen install question

Posted: July 8th, 2012, 4:05 pm

by SilverXJ

According to Lee @ Hesco it was to stabilize the main caps.

The main reason for the main girdle was to stabilize the main cap after the blocks were lighten by 40 lbs.

And just to clarify you don't need studs, like ARP stud kit, you just need to use a set of factory bolts with the studded head.

Re: Golen install question

Posted: July 9th, 2012, 6:33 am

by doublins

SilverXJ wrote:According to Lee @ Hesco it was to stabilize the main caps.

The main reason for the main girdle was to stabilize the main cap after the blocks were lighten by 40 lbs.

And just to clarify you don't need studs, like ARP stud kit, you just need to use a set of factory bolts with the studded head.

FWIW my machinist insists it´s not a girdle as it´s way too thin, and instead is a windage tray, meant to strip oil off the crank to diminish HP losses. Whatever it is, I kept it.

Re: Golen install question

Posted: July 9th, 2012, 7:02 am

by SilverXJ

He is wrong. Windage trays usually cover a much greater area than that and are made of screens and/or louvers. A windage tray also does not need to be that thick. Google windage tray to see what I am talking about.

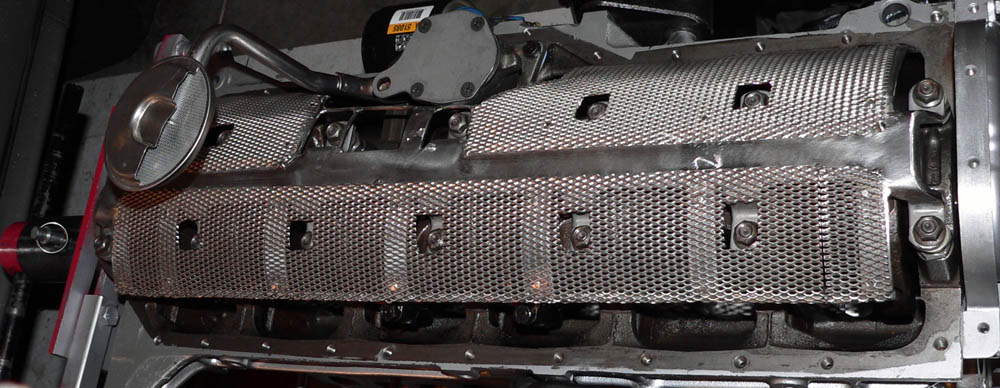

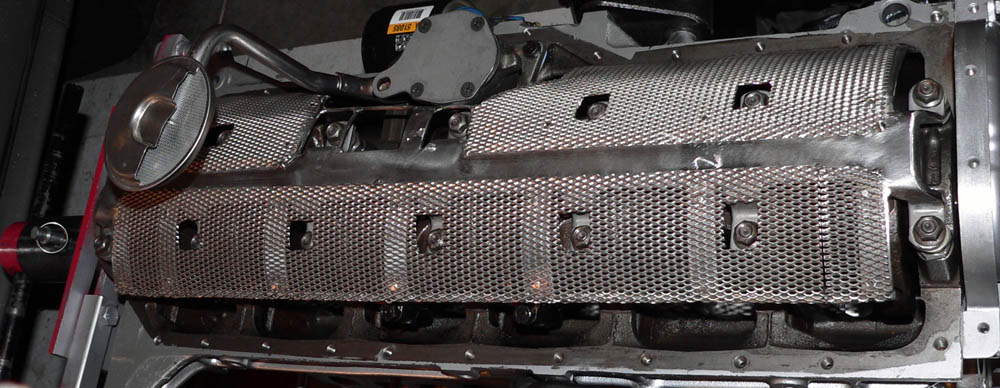

This is a windage screen I made off the girdle:

Re: Golen install question

Posted: July 9th, 2012, 2:47 pm

by casual

SilverXJ wrote:

This is a windage screen I made off the girdle:

Please any instructions on how you did this? Any bad side effects? Like a longer drain time or anything?

Re: Golen install question

Posted: July 9th, 2012, 5:09 pm

by SilverXJ

More pics here:

http://www.jeepstrokers.com/forum/viewt ... &start=540

I took the stock girdle, welded some strips to it then some rods to reinforce it and hold the screen at the outer edges. I used a Moroso screen (IIRC) and used stainless nails as rivets and welded it in places as well. The strips were formed into a curve to conform with the oil pan prior to welding. Keep in mind that the screen and only go in one direction in reference to the crank. If I did it again I would probably use thinner strips and/or less of them. But I was concerned with supporting the screen as much as possible do it will not fatigue and crack over time. There is actually a lot of movement and vibration down there. The pan was massaged a bit previously, and I did have to bend the screen a bit after it was installed to fit the pan.

They are 0 draw backs. It will remove air from the oil as well as remove oil being slung off the crank.

Re: Golen install question

Posted: July 9th, 2012, 8:05 pm

by superj

this is a bmw windage tray. just so you can see the different types of windage trays.

Re: Golen install question

Posted: July 10th, 2012, 6:38 am

by SilverXJ

That is actually a crank scrapper. A bit different in the way it functions, but similar purpose. It is supose to be in very close contact to the crank and rod ends. Some may even touch if they have some flexible material where the two meet. Here is one installed:

Crank scrapers for our engines:

http://crank-scrapers.com/amc.html

Re: Golen install question

Posted: July 10th, 2012, 1:59 pm

by superj

dang it, your right. man, i cannot remember anything lately.

Re: Golen install question

Posted: July 11th, 2012, 5:14 pm

by casual

SilverXJ wrote:More pics here:

http://www.jeepstrokers.com/forum/viewt ... &start=540

I took the stock girdle, welded some strips to it then some rods to reinforce it and hold the screen at the outer edges. I used a Moroso screen (IIRC) and used stainless nails as rivets and welded it in places as well. The strips were formed into a curve to conform with the oil pan prior to welding. Keep in mind that the screen and only go in one direction in reference to the crank. If I did it again I would probably use thinner strips and/or less of them. But I was concerned with supporting the screen as much as possible do it will not fatigue and crack over time. There is actually a lot of movement and vibration down there. The pan was massaged a bit previously, and I did have to bend the screen a bit after it was installed to fit the pan.

They are 0 draw backs. It will remove air from the oil as well as remove oil being slung off the crank.

So would you say to do the middle 5 sections where the main bolts are..and leave the 2 small ends open? How would you do it if you did it again?