1bolt wrote:I was thinking maybe you could repost all the info you had, just so this forum would have it, never know someone else might want to take the ball up and keep it rolling. You had names and numbers, the parts numbers for the

roller lifters that fit the AMC I6 and the mod that was needed to get them into the engine.

There's probably some good reason why the blank needs to be cast into a "blank" instead of just using a hardened steel billet and programing a CNC lathe to cut it to spec...

It seems to me any fair sized machine shop with a CNC lathe could completely manufacture the

cam in either a finished grind or with lobe circles so it could be custom ground...

But again not knowing that much about Cams, I don't know if a

Cam needs some level of flex to work properly (like rods do) so maybe billet steel is too hard or there's some other reason. If it needed to be it could even be machined from forged billet... I bet that wouldn't have a Harmonic problem

I will dig up all the spec's i have but lets first start with the lifters...........This idea couldn't even begin with out a FIRST figuring out how to get a

roller lifter in thru that tight area.....let alone attach the

roller lifter so that they stay put.

A flat tappet lifter must rotate in it bore or it will FAIL ...........a

roller lifter must stay still in it bore so that the wheel can roll up and down the

cam lobe.

This has been the hang up from any body going any farther then the statement

"It sure would be nice to have a roller cam in our 4.0L/strokers"

There is just no room in there for the flat plate type

Roller Lifter (like what is us in the small block Chrysler engs.....and a lot of others)

Many thru out all kind of thought and idea how we could make this work, including my self..........But all would require special made

roller or special machinging to make it stay put in the bore.

Then

Delk(a member here!)Came up with the home run!!!!!!!

And he can explain it better then i.........and hopefully will post up about it.

Basically it is AMC big block

Roller lifter(

Hyd) and it hold a part of lifters from rotating by a steal plate, or strap if you will, at the top of the paired lifters.

Delk got a set of these lifters and started experimenting on his spare block....and found a way to make it all work out just fine.

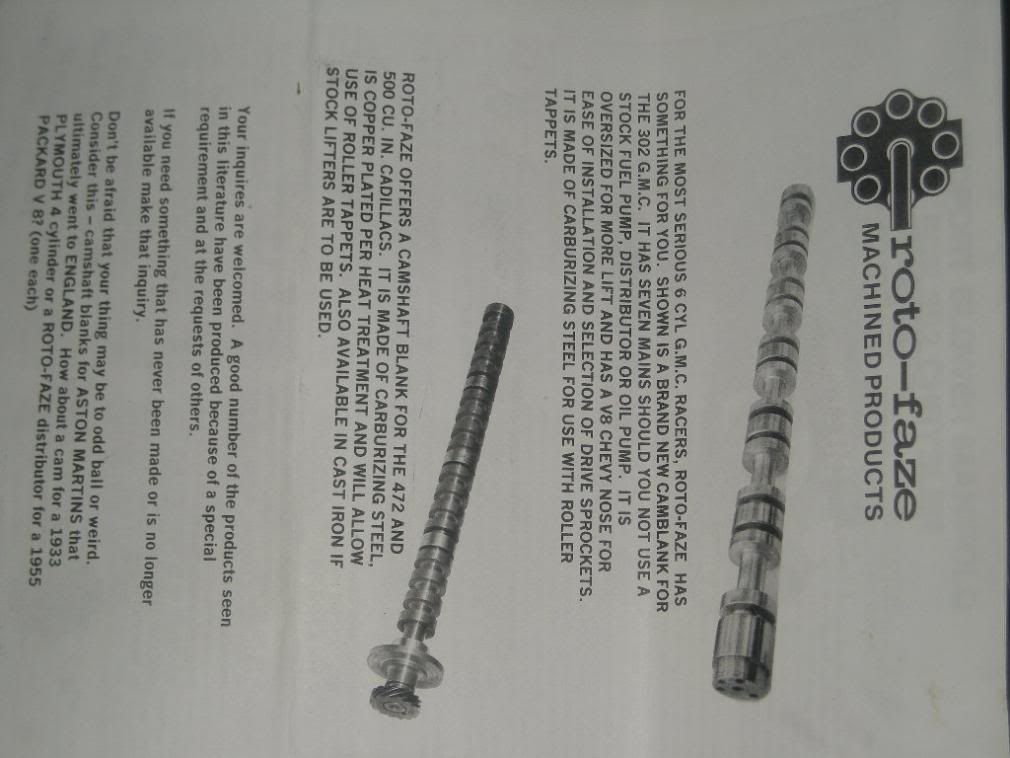

One of the other guy....which i believe is here also, got a hold of Joe at Roto Faze(I will dig up the proper spelling an address later

) and started the ball rolling......But didn't have the time to dedicate to this project, and kinda sorta got past on to me.

We ended up sending Joe 3 different

cam for evaluation, 258, a 93 and 99 4.0L What we found was that the 258 and 93 4.0L were the same casting except that the 4.0L didn't have a lobe for fuel pump.................The 99 #1

cam jurnal was larger and us a

cam plate to keep the

cam from walking back and forth instead of the

cam spring and button of the 98 and older.

We also found that the up to 98 us a different

cam sprocket attachment then the 99 and newer...........It been two long but i believe the 99 and newer us a key way in the shaft and and the 98 and older us a pin to keep the

cam sprocket in time with the

cam.

So since you can us a 98 in a 99 with the addition of the spring and pin.......But you can't us a 98 and older in a 99+ because there is no provision for

cam thrust plate that replace the spring and pin set up in the earlier ones it was decided that the new "

Hyd roller cam" was going to be designed off of the 98 and older, with the fuel pump lobe added (because it wouldn't cost any more to add it) for those that would be using a carb on there eng.

NOTE: the after market cams are designed the same way(Minus the fuel pump lobe) they say for 98 and older 4.0L but when you call then up they say you just need to us the 98 timing chain, sprocket W/the spring and pin set up!

As far as what kind of stock Joe would be using, will he would know better then i so i left that up to him......I know its not cast, but what spec of material.....I really don' t know.

Joe @ Roto-faze has built many one of a kind

roller cams From flat head fords to V6 Buick 12 syl flat head and V8 Ferraris and Maserratis as well and antique vehicles such as a Model A Ford or a V12 Cad that he put into a '34 ford coupe and ran on the EL Mireage Dry lake bed.

Joe make all kinds of stuff,...like a "point" distributor that he clames will turn a eng at 10,000 rpm with out a miss.........Built the original "ISOPORT" BLOWER MANIFOLD FOR THE OLD 392 CHRYSLER HEMI............He even build custom conecting rods(No, don't even want to start down that road

)

He is not much of a Internet guy, he like to talk on phones and mail you info ..........his buddy did set up a Internet sit for him last year but there wasn't much on there then.

here is the like if you want to go check it out

roto-faze.com

One of the biggest cost of the

cam processes is the cutting of the distributor teeth on the

cam shaft it's self.........

I will come up with prices and part numbers tomarrow but thats a good start.

Flash